Laser Air Compressor Comparison: Purity & Stability

When you're specifying a laser air compressor, don't lead with pressure numbers. The real differentiator between systems that deliver clean, glass-smooth cuts and those that leave you chasing defects is air quality (oil-free, moisture-free, particle-free delivery at the laser head).[1] Most shops focus on PSI first. That's backwards. Pressure is the easy part; purity is where failures hide. For a clear explanation of specs, see our CFM vs PSI guide.

Why Laser Cutting Demands Precision Manufacturing Compressors

Laser cutting has fundamentally different air requirements than pneumatic tools. A framing nailer tolerates some oil mist. A spray gun needs clean air. A laser cutting head, with its optical path and precision nozzle, cannot afford contamination.[1][2] A single water droplet can scatter the beam, cause edge quality loss, or (over weeks) corrode the lens and nozzle. Oil particles degrade cutting performance and build residue on optics. Dust blocks the air channel.

The laser cutting industry has moved beyond nitrogen gas because compressed air, when treated properly, now costs 75% less and delivers equivalent cutting results.[3] That shift only works if the compressor system includes multi-stage filtration, active drying, and pressure stability at the cutting head.

Clean, dry, stable air makes finishes look inevitable.

I once watched a shop battle orange peel and edge tearing on stainless-steel cuts. They tested laser power, checked nozzle wear, realigned the optics. Everything looked right on paper. When we measured pressure at the cutting head (instead of trusting the tank gauge) it dropped from 1.4 MPa at the compressor to 0.8 at the nozzle. Wet lines feeding the system and a compressor sized for theoretical demand, not real duty. They upgraded to a two-stage screw compressor with an adsorption dryer and aftercooler, installed a regulator at the cutting head, and replaced the undersized hose. Edge quality improved within 24 hours. Rejects fell by 90% in a week.[2]

That outcome wasn't luck. It was the result of treating air delivery as a system, not an afterthought.

Core Compressor Types for Laser Cutting: Comparison Framework

Compressor selection for laser cutting air purity begins with understanding which designs deliver the air quality characteristics your system demands.

Piston and Entry-Level Compressors

Piston compressors are affordable and mechanically simple, but they oscillate during compression, generate more heat, and typically require frequent oil top-ups.[2] For laser cutting, they fall short because:

- Pressure delivery is pulsed, not stable, stressing regulators and drying equipment.

- Oil carry-over into the air stream is common, requiring aggressive multi-stage filtration to reach acceptable purity levels.

- Duty cycles are limited; continuous laser cutting work forces thermal shutdowns.

- Noise levels (80+ dBA) make workshop integration difficult.

Piston units suit entry-level laser systems (under 3 kW) in light-duty environments, but they are not the platform for production environments.[1]

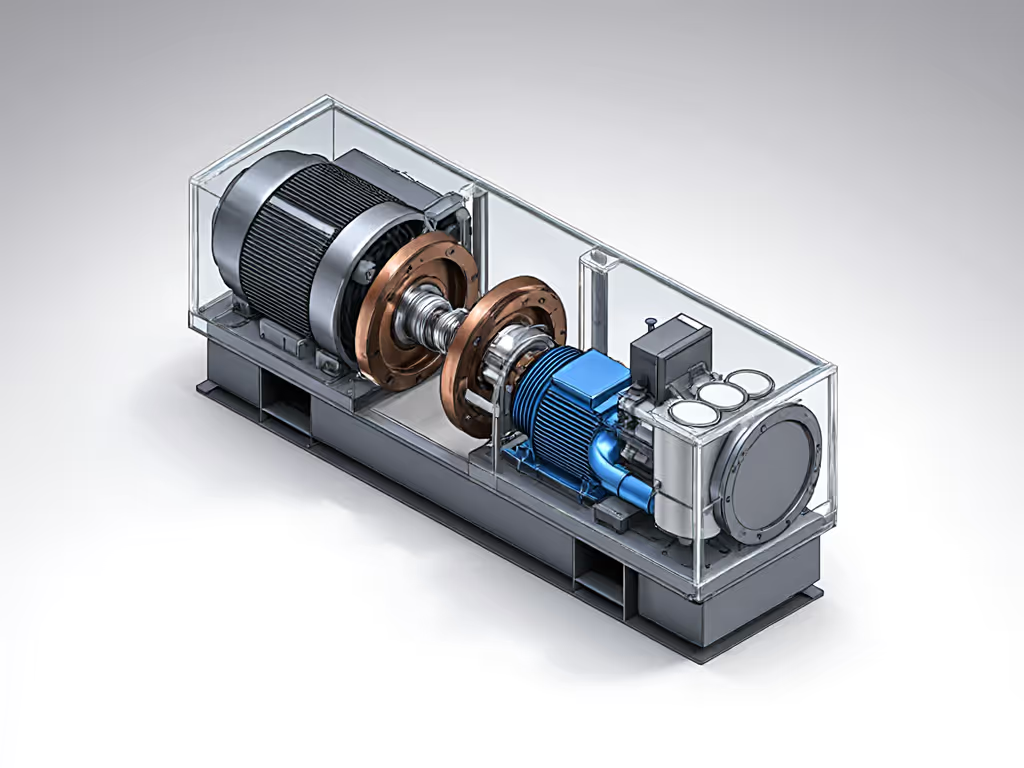

Rotary Screw Compressors: The Mainstream Choice

Rotary screw air compressors have become the industry standard for laser cutting because they compress air smoothly and continuously.[2] Here's why they excel:

Stable Pressure Delivery: Screw designs rotate at fixed speeds (or variable with VSD technology), producing constant air flow without pulsation. This is critical for beam stability requirements in precision laser work, as a wavering pressure input to the cutting head directly degrades edge quality.

Integrated Dryer Options: Mainstream screw units come equipped with refrigerated dryers and adsorption towers, bringing pressure dew point down to -20°C to -40°C.[1] That level of moisture removal prevents water vapor from condensing in lines or at the cutting nozzle.

Energy Efficiency: Permanent Magnet Variable Speed Drive (PM VSD) screw compressors adjust motor frequency in real-time based on demand, cutting electricity consumption by 20-30% compared to fixed-speed units operating at idle.[1][4] For a 1.3-1.6 MPa system running 8+ hours daily, that savings compounds quickly.

Modular Design: Screw compressors are often sold as integrated units (compressor, tank, dryer, and filter bank pre-matched and internally optimized at the factory).[1] Field assembly introduces pressure-drop risk; integrated systems eliminate that weak point.

Air Purity Specifications: Filter, Dew Point, and Micron Ratings

Once you've selected a screw platform, laser system integration depends entirely on the treatment stages downstream of the compressor.

The Four-to-Five-Stage Filter Hierarchy

Industrial laser air solutions follow this cascade:

- Intake Filter (100-5 µm): Removes workshop dust and airborne particles before compression, extending downstream filter life.

- Oil Removal Filter (3 µm): Coalesces oil mist carried from the compressor cylinder into liquid droplets that drain to the tank.

- Activated Carbon Filter (0.01-0.1 µm): Removes odor and trace oil vapor that escaped the coalescing stage.

- High-Precision Final Filter (0.001 µm): Captures particles small enough to scatter the laser beam or block nozzles. This stage is non-negotiable for optical systems.[4][5] Match your laser's requirements to the correct air class with our ISO 8573 air purity guide.

- Optional Sterile Air Filter: For ultra-clean environments, a 0.0001 µm final polish; used in specialized cutting operations.

A five-stage filter bank reduces particle carry-over to levels that protect optics and maintain edge quality over thousands of cutting hours. Skipping stages invites contamination; oversizing stages beyond the compressor's dirt load wastes pressure and cost.[4]

Dew Point: The Hidden Pressure Metric

Moisture is invisible until it condenses. Pressure dew point (PDP) is the temperature at which air becomes saturated and water begins to form. For laser cutting:

- Refrigerated dryers lower PDP to -3°C to 3°C.[1] Adequate for most cutting; acceptable for non-metallic materials.

- Adsorption dryers achieve -20°C to -40°C.[1][4] Required for thick steel and stainless-steel work, and for any system where moisture risk is unacceptable. Not sure which dryer type fits your shop? See our air dryer comparison covering refrigerated, desiccant, and membrane options.

A compressor shop measuring ambient relative humidity at 60% and 25°C will see significant condensation if the dryer isn't sized to handle peak demand.[1] Many shops skip dew-point testing until failures occur. Measure it first: if your dew point exceeds -3°C, upgrade immediately. Don't guess.[1]

System Architecture: Pressure Regulation at the Cutting Head

Many shops install a tank-mounted regulator and call the system complete. That's a common mistake.

Pressure drop across hoses, fittings, and manifolds is real and measurable. A 1.5 MPa signal at the tank becomes 1.3 at a distant regulator, and 1.1 at the cutting head if hose diameter is undersized or the run is long. That 400 kPa loss degrades cutting speed and edge quality.

The solution: Install a pressure regulator immediately upstream of the laser cutting head, after all filtration but before the machine inlet. This ensures that whatever pressure the cutting system requires (typically 1.3-1.6 MPa), it receives, not theoretical pressure from the tank, but measured, stable pressure at the point of use.

Pair this with hose sizing matched to flow demand: for a 6 kW laser system at 1.4 MPa, use 3/8" (10 mm) hose minimum for runs under 30 meters; larger diameter for longer runs.[2] Specify fittings rated for the working pressure and confirm pressure at the cutting head with a test gauge, twice, at idle and under load. This practice eliminates guesswork and produces repeatable results.

Finish to spec, repeatably.

Comparative Specifications: Matching System to Load

| Laser Power Range | Recommended Pressure (MPa) | Compressor Type | Dryer Standard | Expected Air Quality (PDP) | Primary Application |

|---|---|---|---|---|---|

| 1-3 kW (Entry) | 0.8-1.2 | Compact Rotary Screw | Refrigerated | -3°C to 3°C | Non-metallic, thin sheet |

| 3-6 kW (Mid-Tier) | 1.3-1.5 | PM VSD Two-Stage Screw | Refrigerated + Adsorption | -20°C to -30°C | Mixed materials, production |

| 6-12 kW (Industrial) | 1.4-1.6 | VSD or Fixed-Speed Screw | Adsorption + Aftercooler | -30°C to -40°C | Thick steel, stainless |

| 12 kW+ (High-End) | 1.6-2.5 | High-Pressure Screw or Booster | Electronic-Grade Adsorption | -40°C or lower | Precision metalwork, nitrogen replacement |

Key observation: Energy efficiency and total cost of ownership favor PM VSD screw units in the 3-12 kW range. These systems save 20-30% on electricity, run cooler, and integrate drying at the factory. Return on investment (ROI) over five years often exceeds 25-35% when compared to fixed-speed or piston alternatives.[1]

For systems above 12 kW cutting thick materials continuously, high-pressure booster compressors (1.6-3.0 MPa) enable nitrogen substitution, recovering the higher capital cost in reduced gas expenses within 6-10 months.[1]

Integration and Monitoring: Verification Over Faith

Once the system is assembled, don't assume it works. Precision manufacturing compressors demand verification:

- Measure pressure at the compressor outlet (tank gauge) and again at the cutting head (test port). Document the difference. If it exceeds 0.2 MPa, investigate hose diameter, fitting restrictions, or filter element clogging. Use our troubleshooting guide to diagnose pressure drop, leaks, and overheating under load.

- Test air flow (CFM or liters/minute) at the working pressure during a cutting cycle, not at idle. Theoretical CFM is useless; actual CFM at 1.4 MPa is what sustains cut quality.

- Log dew point weekly using a portable dew-point meter. If it rises above specification (typically -10°C minimum for production work), the dryer cartridge needs replacement or the dryer is undersized for ambient humidity.

- Monitor filter differential pressure. When the final filter reaches its change-out pressure (usually a 0.3-0.5 MPa drop across the element), replace it. Ignoring this invites particles past the filter.

These measurements take minutes and prevent the failures that cost hours and scrap material.

Conclusion: System Thinking Over Component Shopping

Laser air compressor comparison is not a single-product choice; it's a system decision. Select a screw compressor sized to your laser power and duty cycle, specify filtration to remove oil, particles, and water down to laser-safe levels, install active drying to control moisture, and place a regulator at the cutting head to verify and maintain stable pressure where it matters.

Shops that treat air delivery as an afterthought buy compressors twice (once in hope, once in desperation). Shops that approach it systematically achieve edge quality that's consistent, repeatable, and predictable.

Start by measuring your current system: tank pressure, cutting-head pressure, dew point, and air flow under load. If your cutting head pressure is more than 0.2 MPa below tank pressure, or if your dew point exceeds -3°C, you've found your first upgrade target. Diagram the full air path (compressor, tank, dryer, filter bank, hose runs, regulator, and cutting head) and identify where clean, dry, stable air is being lost. That map is your roadmap to finishing on spec, repeatably.

Further exploration into your specific laser system's air requirements (check the OEM manual for flow, pressure, and purity specs), coupled with testing your current air quality, will reveal whether your compressor is undersized, over-dried, or improperly regulated. From there, the upgrade path becomes obvious and justified by data, not marketing claims.

Related Articles

Quiet Woodworking Air Compressors: Real-World Comparison

Vertical Farming Compressors: Precision Humidity Control

Museum Preservation Compressors: Truth Beyond Specs