Air Compressor Troubleshooting: Fix Real-World Pressure Problems

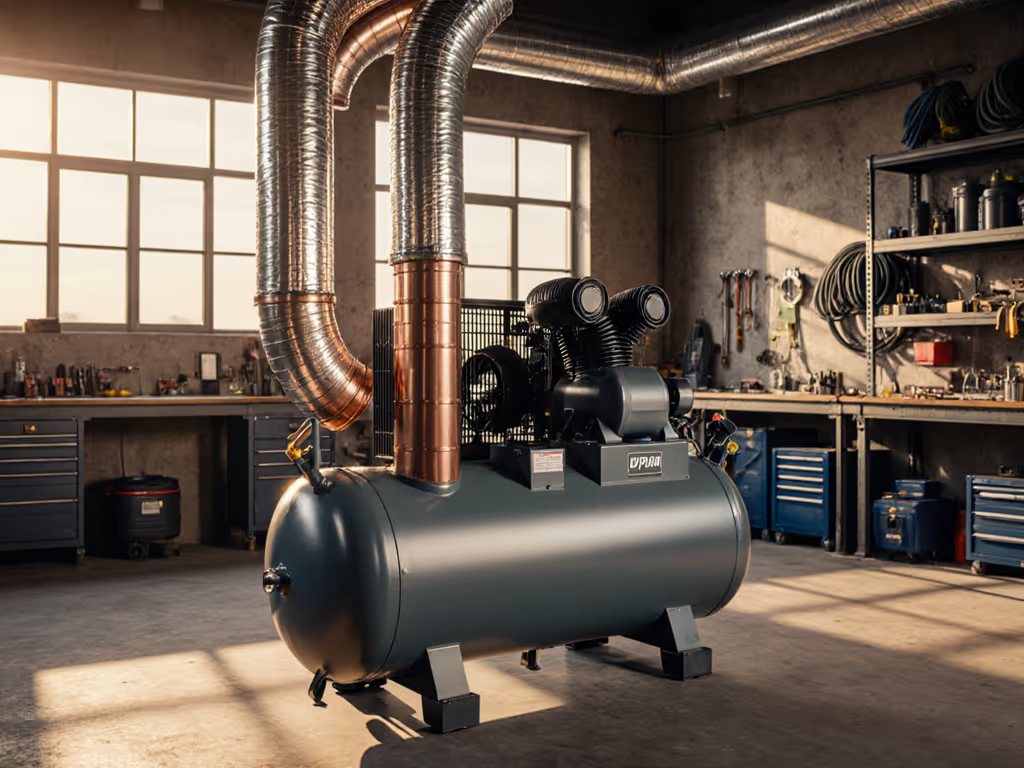

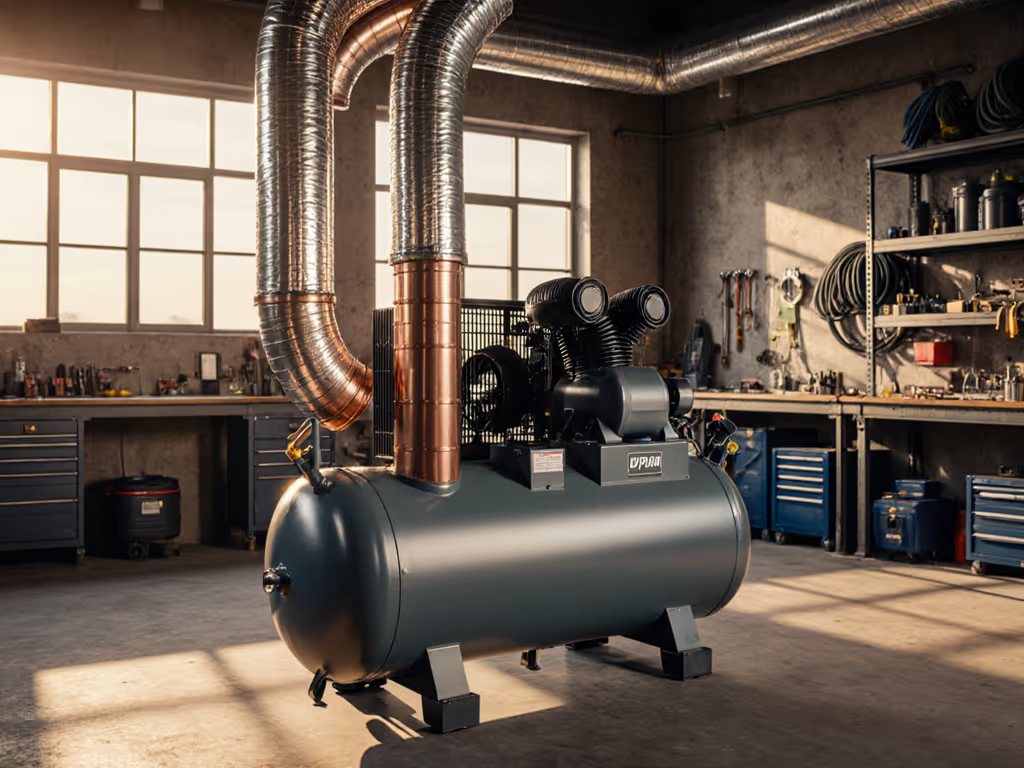

When your spray gun delivers orange peel instead of glass-smooth finishes, or your impact wrench loses torque mid-job, air compressor troubleshooting becomes more than a chore (it is the difference between profit and rework). Most common compressor problems originate not from the compressor itself, but from overlooked pressure drops, moisture, and system imbalances between tank and tool. Finish quality is a system result: clean, dry, and stable pressure beat guesswork every time.

As a spray finishing specialist who's watched countless shops chase phantom "paint issues," I've seen 90% of failures stem from undiagnosed pressure loss at the point of application. Let's cut through the noise with a field-tested diagnostic sequence that targets the actual culprits, not just the symptoms.

Step 1: Verify Pressure at the Tool, Not the Tank

Most technicians check pressure at the compressor tank gauge, then call it a day. But pressure measured at the tank rarely matches what your tool receives. In one case, a body shop battled persistent fish-eyes, blaming the paint supplier. We measured 100 psi at the tank, but just 28 psi at the spray gun trigger. Those missing 72 psi vaporized their finish quality.

Your Pressure Verification Protocol

- Install a calibrated inline gauge directly at the tool connection point (before quick disconnects)

- Document pressure during operation - not just at idle (e.g., 92 psi at tank drops to 68 psi when HVLP gun triggers)

- Note hose specifications: 50-foot hose? Check ID: 3/8" vs. 1/4" creates 22 psi difference at 25 CFM

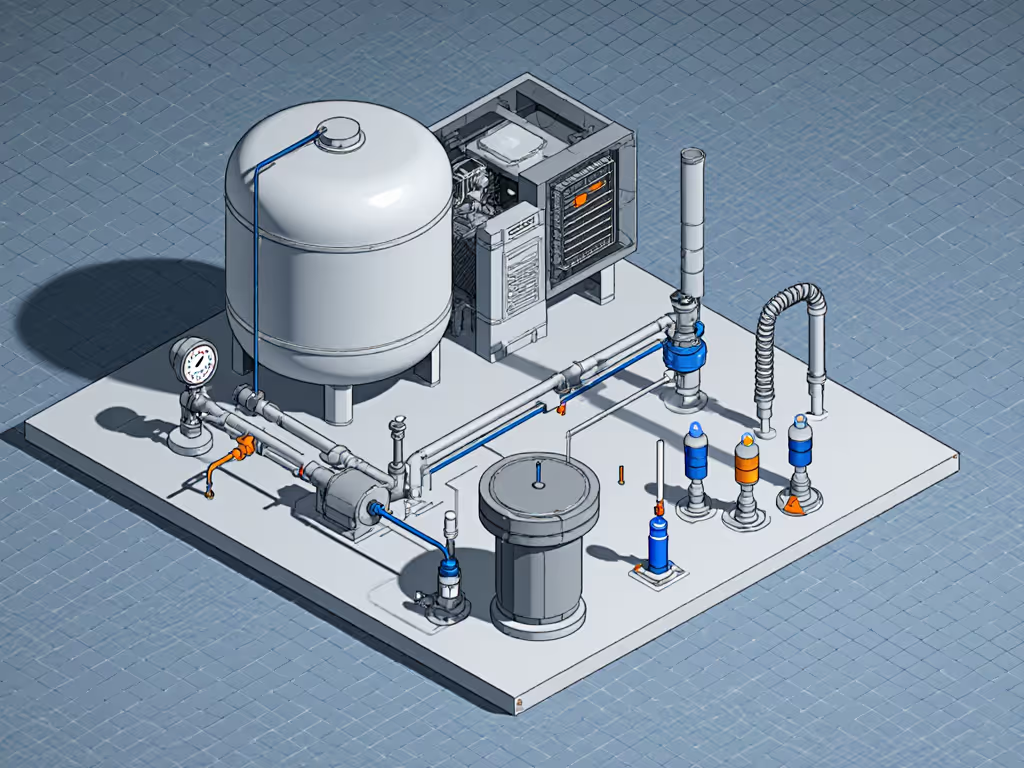

- Map pressure drops stage-by-stage: tank → filter → regulator → hose → tool

Dry air, fewer defects.

A 3/8" hose reduces pressure drop by 50% compared to 1/4" at 25 CFM. If your regulator sits at the compressor instead of the tool, you're compensating for losses that already occurred (like trying to fix a leaky bucket by adding more water at the source).

Step 2: Execute Targeted Air Leak Detection

Leak detection isn't about finding any leak (it is about prioritizing leaks that impact your workflow). A 1/16" hole wastes 3.5 CFM at 100 psi, but many shops waste hours hunting negligible leaks while missing critical ones in pressurized lines.

Precision Leak Hunting Methodology

- Shut off all tools and isolate the compressor from the system

- Monitor pressure decay for 5 minutes: 5+ PSI drop = critical leak zone

- Check high-impact zones first:

- Quick disconnect couplings (most common failure point)

- Regulator inlet/outlet connections (check O-ring seating)

- Drain valves left partially open

- Hose splices and damaged sections (look for abrasion points)

- Use ultrasonic detectors for sub-3 CFM leaks - audible checks miss 70% of losses

Document each leak location with estimated CFM loss. A single faulty quick disconnect might waste 8 CFM, enough to starve an HVLP gun drawing 12 CFM at 40 PSI. This is where targeted air leak detection transforms guesswork into quantifiable repair priorities.

Step 3: Diagnose Low Pressure Issues Through the System

"Low pressure" usually means "insufficient flow at working pressure," a critical distinction. Your compressor might deliver 150 PSI but still starve tools if airflow collapses under demand. For a clear breakdown of CFM and PSI at working pressure, see our CFM vs PSI guide.

Flow Diagnostic Sequence

- Validate compressor output with calibrated flow meter:

- Measure actual CFM at target pressure (e.g., 22 CFM @ 90 PSI)

- Compare against tool requirements at working pressure (not max PSI)

- Check filter stages in sequence:

- Coalescing filter (0.01-micron): pressure drop >7 PSI indicates saturation

- Particulate filter (5-micron): check differential pressure gauge

- Carbon filter (vapor removal) is an often overlooked source of 10+ PSI drop

- Inspect aftercooler performance:

- Ideal discharge temperature: ambient + 15°F

-

100°F indicates fouled heat exchange (common in oil-lubricated units)

- Verify regulator placement:

- Regulator at tool = 3-5 PSI variation

- Regulator at tank = 15-25 PSI swing under load

This systematic approach to low pressure issues reveals why many shops install oversized compressors yet still face performance gaps, because their filtration stage creates hidden pressure loss. Clean, dry, stable air makes finishes look inevitable.

Step 4: Solve "Compressor Won't Start" Beyond the Basics

When a compressor won't start, 80% of shops immediately check power and oil, critical first steps, but rarely the full story. Thermal overload trips often signal deeper system imbalances.

Advanced Diagnostic Protocol

- Analyze startup sequence:

- Humming sound? Check start capacitors (measure μF rating)

- Click but no spin? Verify unloader valve function

- Immediate shutdown? Monitor thermal cutoff reset time

- Assess ambient conditions:

-

80°F ambient requires 20% CFM derating

-

70% RH increases moisture load by 35%

- Validate electrical supply:

- Voltage drop >5% during startup causes 30% torque reduction

- Measure inrush current (should be <6x running amps)

- Check for backpressure:

- Faulty check valve = air backflow into pump head

- Blocked discharge line = resistance on startup

This data-driven approach to compressor won't start scenarios prevents misdiagnosis. One mobile detailing rig kept tripping thermal overload, not from motor issues, but because their 50-foot hose created 18 PSI backpressure during startup.

Step 5: Implement Real Overheating Solutions Based on Root Cause

"Overheating" is not a single problem (it is three distinct failure modes requiring different overheating solutions).

Thermal Problem Matrix

| Symptom | Likely Cause | Quantitative Fix |

|---|---|---|

| Gradual temp rise during operation | Insufficient cooling airflow | Maintain 300+ CFM cooling per HP; verify 18" clearance around unit |

| Sudden shutdown at consistent intervals | Moisture overload in aftercooler | Install 35°F dew point dryer; verify drain cycle frequency |

| High discharge temp but normal oil temp | Plugged intercooler (two-stage) | Clean fins with compressed air; replace if pressure drop >12 PSI |

Never address symptoms alone. One framing contractor's compressor kept overheating at 102°F ambient, until we discovered their 1/4" intake hose created 8" H₂O restriction, reducing volumetric efficiency by 22%. Ambient temperature matters, but system design matters more.

Conclusion: Systematic Air Management, Not Band-Aid Fixes

Effective air compressor troubleshooting requires treating your compressed air system as an integrated circuit, not a collection of isolated components. When pressure drops murder your finish quality or tool performance, you're seeing symptoms of upstream failures.

Start at the tool, measure actual working conditions, and work backward through each treatment stage. Document pressure, flow, and dew point at every transition point. The data will reveal where your system leaks performance, often in places you never suspected.

For shops serious about eliminating guesswork, I've developed a free Pressure Mapping Worksheet that walks you through each measurement point with industry-standard tolerances. It's saved countless painters from blaming their paint when the real culprit was wet air and unstable pressure. Because, at the end of the day, dry air means fewer defects, and that is a finish any professional can be proud of.

Related Articles

Robotics Air Compressor Integration: Precision CFM at 90 PSI

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

AI Compressor Maintenance: Predict Failures Before They Happen