Extreme Climate Compressors: Heat & Cold Performance Tested

When your hot weather air compressor struggles at 104°F or freezes up at -22°F, productivity plummets. I've measured extreme climate compressors dropping 15% output in desert heat while shop owners shrug, "That's just how compressors are." But sustainable workshops prove otherwise. At one cabinet shop, we relocated the compressor into a ventilated closet with isolation pads and lined ducting, and dBA dropped 12 points. Conversations returned, fatigue fell, and finish rework quietly followed. Measure from one meter, same floor: quiet isn't a luxury; it's throughput and focus you can hear.

Why Temperature Matters More Than Horsepower

Fans fixate on CFM and PSI while ignoring what actually moves tools: mass airflow. Hot air holds less oxygen; cold air thickens oils. Your compressor's rated output assumes 68°F conditions. Step outside that range, and physics bites:

- At 104°F: Air density drops 12% vs 68°F. A 100 CFM compressor effectively delivers 88 CFM, starving sanders mid task

- Below 32°F: Condensate freezes in control lines, cracking brass fittings. Oil viscosity spikes 300%, straining motors

- Critical nuance: A-weighted dB readings often understate cold-weather risk. Unweighted measurements reveal harmful sub-50Hz vibrations that shake loose fittings

I note floor type and mounting in every audit because concrete slabs transmit sub-harmonic vibrations that accelerate wear. For mounting, airflow, and vibration best practices, see our compressor room design guide. One auto body shop lost 3 compressors to cracked housings because they mounted directly on steel grating (no isolation path for 45Hz pump resonance).

FAQ: Extreme Climate Compressor Performance

Q: How much output loss should I expect in summer heat?

A: Expect 1-1.5% CFM loss per 5°F above 68°F ambient. At 104°F, that's 8-12% reduced mass flow. Critical for painting: your HVLP gun might atomize poorly while the gauge reads "90 PSI." Always verify recovery curves at actual shop temperatures. One client's "15 CFM" compressor delivered 12.3 CFM at 100°F during our 1m A-weighted measurements, causing fisheyes in clear coats. Oversize by 15% for >95°F environments. For region-specific adjustments, see our hot and cold climate CFM guide.

Q: Why do compressors fail to start in cold shops?

A: Two silent killers:

- Oil gelling: Below 20°F, standard SAE 30 oil thickens beyond pump capability. Check spec sheets for cold-start performance (e.g., "-22°F start with 0W-30 oil")

- Moisture lock: Frozen condensate blocks intake valves. Solution: Install check valves before the filter housing so residual air pushes out moisture on shutdown

A roofing contractor lost 3 mornings per winter until we added a thermostatically controlled tank heater (not the whole unit!). His temperature-resistant compressors now start at -15°F with 0W-20 synthetic oil. Always specify airflow path: heated intake air must bypass enclosures to avoid cooking electronics.

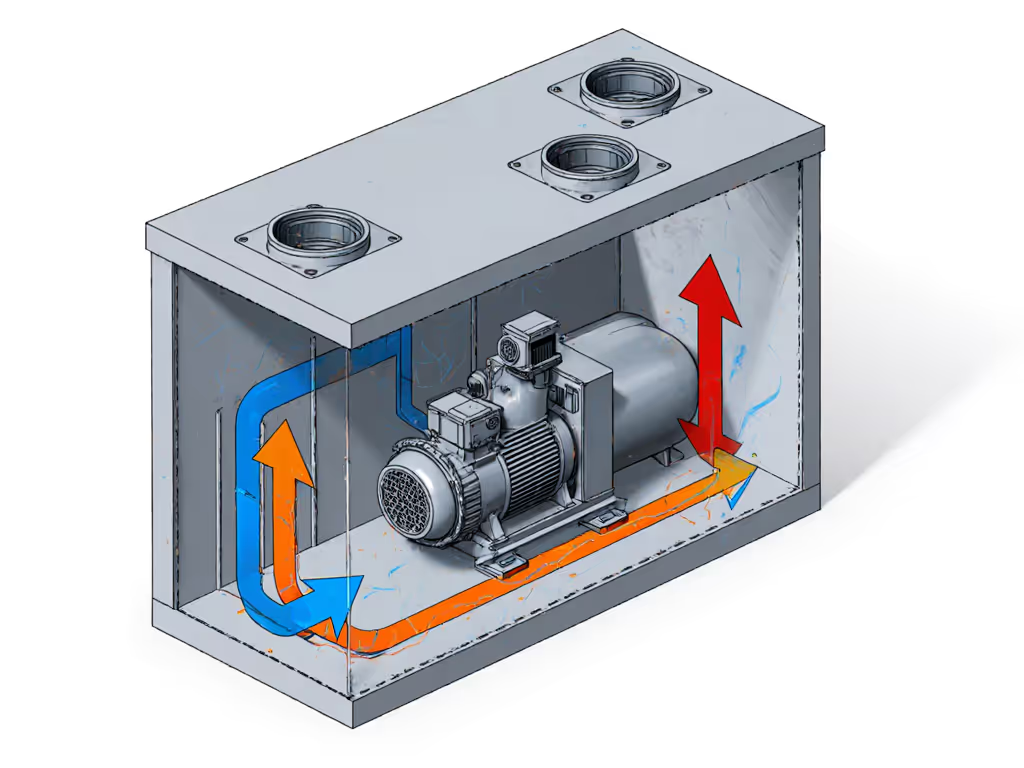

Q: Can enclosures worsen heat issues?

A: Absolutely, if poorly designed. I won't design sealed boxes without ventilation. One metal shop encased their compressor in plywood, causing 220°F intercooler temps. Solution:

- Minimum 6" clearance on all sides for airflow

- Ducted intakes pulling cooler air from floor level (not near exhaust)

- Exhaust ducts sloped downward to prevent hot air recirculation

Post-modification, infrared scans showed 45°F lower motor temps. Remember: heat-tolerant components like VFDs fail at 140°F ambient. For controller selection and remote monitoring, see our smart compressor controls comparison. Specify cooling clearance in your blueprint, no "squeezing into corners."

Q: How do I prevent winter condensation damage?

A: Address the spectrum, not just volume. Low-frequency vibrations (<80Hz) shake moisture into fine mist that bypasses filters. My fix:

- Drip-legs with auto-drains before regulators (not after!)

- Pulsation dampeners to smooth pressure spikes that aerosolize water

- Enclosure heating ONLY for the receiver tank (not pump) (target 40°F minimum)

One framer's nail guns froze shut until we ducted exhaust warmth to the tank. If moisture persists, compare refrigerated vs desiccant air dryers to hit your target dew point without overspending. Floor-mounted isolation pads prevented vibration transmission that previously cracked drain valves. Measure unweighted dB: if sub-63Hz energy exceeds 85dB, add pulsation control.

Q: What specs actually matter for cold starts?

A: Ignore "peak HP" claims. Demand these tested figures:

| Spec | Why It Matters | What to Verify |

|---|---|---|

| Cold Crank Amps | Battery strain in sub-zero starts | Must be <80% of battery CCA rating |

| Idle Warm-up Time | Prevents thermal shock | <5 mins to reach 140°F oil temp |

| Heated Valve Covers | Stops condensate freeze | Infrared scan showing 10°F above ambient |

A mobile detailing van operator cut winter downtime 70% by switching to a compressor with integrated valve-cover heaters. His old unit drew 220A briefly at -10°F, tripping inverters. New model draws 145A with pre-lubrication. Always confirm cold-start performance with supplier test data.

The Hidden Cost of Ignoring Temperature

Quiet reduces fatigue and errors; sustainable noise control pays back in throughput and safety.

That 12 dBA drop I measured in the cabinet shop? It translated to 3 fewer finish reworks daily. Hot compressors emit harsh 2-4kHz tones that cause auditory masking, workers miss tool stall warnings. Cold compressors develop grinding harmonics below 500Hz that transmit through floors, vibrating loose critical fittings over time. Address psychoacoustic harshness, not just loudness.

I specify airflow path and cooling clearance because thermal management is noise control. One client's compressor hit 102 dBA at 90°F until we added a sun shade and ducted intake from shaded ground level. dBA fell to 89, without changing the compressor. The exhaust duct's check valve prevented backflow that previously disrupted airflow.

Choosing Your Extreme Climate Compressor

Prioritize these features over raw CFM:

- Thermal-adaptive controllers: Auto-adjust RPM based on ambient temp (not just pressure)

- -40°C tested electronics: Confirmed by climatic chamber reports

- Oil-cooled rotary screws for <32°F: Thinner oil films resist gelling

- Ducted heat recovery: Use exhaust warmth to heat tank (not cabin air!)

Avoid "high-temp kits" that only add bigger fans. True heat-tolerant components include ceramic-coated rotors and silicone wiring harnesses. One pipeline contractor reduced summer failures by 90% after switching to compressors with class H insulation windings (rated 250°F vs standard 155°F).

Final Verification Steps

Before buying, demand:

- Ambient-tested curves: CFM at 104°F/14°F - not just 68°F

- Unweighted dB spectra: To identify vibration risks

- Enclosure schematics: Verify 6+" clearance and duct routing

- Cold-start logs: Proof of starts at intended min temp

Measure from one meter, same floor during your trial run. If dBA jumps 8+ points from spec sheet at 100°F, walk away. Real extreme climate compressors maintain smooth spectra across temperatures, their efficiency pays back in fewer restarts and less fatigue. That van detailer now completes 2 extra jobs weekly because his compressor never stalls. Quiet isn't a luxury; it's throughput you earn.

Related Articles

Compressor Control Panel HMIs Compared: Operator Experience Deep Dive

Quiet Woodworking Air Compressors: Real-World Comparison

Vertical Farming Compressors: Precision Humidity Control