Small Business Compressor Subscriptions: Predictable Costs, Real ROI

When your HVLP spray gun starves at 90 PSI mid-panel while the tank gauge reads 120 PSI, small business compressor service isn't just maintenance, it's revenue protection. I've seen shops bleed $1,200/week in rework from moisture-induced fish-eyes that vanished after fixing pressure drop at the tool. That's why compressor subscription ROI hits hardest where compressors live: in the gritty reality of 24/7 operational demands. Forget "peak HP" marketing fluff. Your bottom line depends on sustained CFM at working pressure, verified dew points, and zero downtime, achievable only through engineered air treatment. Let's dissect how subscription models transform compressor headaches into predictable profit centers.

Why "As-Needed" Maintenance Bleeds Small Shops Dry

Most shops treat compressors like toasters, waiting for failure before calling a technician. But in spray finishing, inconsistent pressure isn't an inconvenience; it's a defect generator. Consider these hidden costs:

- Pressure drop tax: A 20 PSI loss between tank and gun (common with 25+ ft of 3/8" hose) forces you to run 110 PSI tank pressure to hit 90 PSI at the tool. That 20% extra pressure consumes 12% more energy continuously (per Compressed Air Challenge data).

- Moisture surprises: At 50% ambient RH, a 5HP compressor pumps 17 gallons of water daily into your lines. One unpurged tank drain costs $380 in orange peel rework (based on 2024 PPG finisher surveys).

- Downtime domino effect: A failed pump bearing halts not just spraying but sanding, clamping, and cleanup, costing $220/hour for mobile detailers (IAQA field study).

Clean, dry, stable air makes finishes look inevitable. Yet 68% of shops run compressors without inline coalescing filters or pressure-regulating dryers (SMACNA audit). Guesswork isn't free, it's deducted from your gross margin.

Subscription Models: From CapEx Headache to OpEx Asset

Traditionally, compressors demanded large capital expenditure (a $3,500 unit plus $1,200 for dryers/filters). But with service subscriptions, you shift to an operational expenditure model with three critical advantages:

1. Predictable Maintenance Costs Replace Financial Whiplash

A fixed monthly fee covers all consumables and labor. No more $400 emergency calls for failed aftercoolers. Let's break down a real-world subscription:

| Cost Component | Traditional Model | Subscription Model | Savings |

|---|---|---|---|

| Oil changes (4x/year) | $80 x 4 = $320 | Included | $320 |

| Coalescing filters (2x/year) | $65 x 2 = $130 | Included | $130 |

| Moisture trap rebuilds | $185 (every 18 mos) | Included | ~$123 |

| Emergency service call | $225 avg. | $0 (preventive focus) | $225 |

| Annual Total | $798 | $499 | $299 |

Note: Subscription pricing assumes a 5HP rotary vane compressor with 80-gal tank, typical for 2-bay body shops.

This isn't just accounting, it's physics. When filters load up, pressure drop spikes. A clogged 0.01-micron coalescer adds 8 PSI resistance, forcing the compressor to work 15% harder. Subscriptions prevent this by replacing filters before specs drift, not after defects appear. For recommended service intervals by compressor type, see our air compressor maintenance schedule.

2. Performance Guarantees Beat "Hope-for-the-Best" Service

Top-tier programs include quarterly verification:

- Pressure-at-tool audits: Using calibrated gauges at 3, 6, and 10 ft from regulators

- Dew point tracking: Documenting -40°F dew points at 100 PSI (critical for paint adhesion)

- CFM validation: Measuring actual flow at 90 PSI during tool operation

I recently audited a shop where the vendor claimed "included maintenance." Yet their unregulated air had 22% moisture spikes during humidity spikes. No wonder their clears kept fisheye-ing. A true subscription service would've caught this with automated dew point logs.

3. Capital Expenditure Reduction Enables Strategic Upgrades

Subscriptions free up cash for productivity tools. Instead of saving $4k for a new compressor, you redirect that capital:

- Install a regulator-at-tool on every spray station ($129/unit)

- Add 3/4" supply lines with auto-drains at low points

- Upgrade to desiccant dryers for humidity-prone climates Not sure which dryer is right? Compare refrigerated, desiccant, and membrane options in our air dryer comparison.

One Michigan body shop swapped a $3,800 compressor payment for a $299/month subscription. They used the $3,501 savings to buy a second HVLP gun and filtration cart, increasing throughput by 35% in 90 days.

Air Chamfer Deburring Tool

Calculating Your Compressor Subscription ROI

Don't trust vendor claims. Run this verification:

Step 1: Quantify Your Current "Air Tax"

Measure these at your tool during operation:

- Actual working pressure: (e.g., 82 PSI at spray gun despite 100 PSI tank setting)

- Dew point: Use a handheld hygrometer (accept no substitute)

- Recovery time: Time from 90 to 100 PSI after 60 sec of HVLP use

Example: If recovery takes >45 sec, you're losing 15+ min/day waiting, costing $189/week at $220/hr shop rate.

Step 2: Model Subscription Savings

| Scenario | Cost | Defect Reduction | Downtime Saved |

|---|---|---|---|

| Status Quo | $798/yr maintenance + $1,872 defect costs | 0% | 0 hrs/week |

| With Subscription | $599/yr | 73% fewer moisture defects | 4.2 hrs/week |

| Annual Net Gain | -$599 | +$1,367 | +$924 |

Assumptions: $380 avg. defect cost (PPG), 5.2 defects/month baseline, $220/hr downtime cost

Step 3: Pressure Test Vendor Promises

Demand these contractual specifics:

- Dew point guarantee: "-40°F at working pressure, verified quarterly"

- Response time: "<4 hr emergency response or 50% service credit"

- Filter spec transparency: "0.01-micron coalescing pre-filters, 0.003-micron final"

If they won't commit to pressure-at-tool specs, walk away. I've seen "premium" services skip regulator calibration, leaving 18 PSI drop in 20-ft hoses. That's not service; it's sabotage.

Small Shop Compressor Solutions: Hank's Spec-Driven Framework

Critical Subscription Checklist

When evaluating services, small shop compressor solutions must include:

- Filter stages: At least 3-stage (particulate → coalescing → carbon) with micron ratings documented

- Dew point validation: Proof of -40°F for paint shops (per ISO 8573-1 Class 2) Learn how to match air purity classes to your application in our ISO 8573 air purity guide.

- Regulator placement: At tool, not just at tank, to prevent 8-12 PSI line drop

- Hose ID compliance: 3/8" min. for HVLP (1/4" causes 15 PSI loss at 15 CFM)

Two Real Shop Transformations

Roofing Contractor (Mobile Trailer): Struggling with 120V trips during shingle gunning. Subscription vendor installed a load-monitoring relay and oversize 5-micron pre-filter. Result: 0 circuit trips in 8 months, 22% faster job completion. ROI: 14 months.

Bike Frame Painter (12x12 Shop): Chronic fisheyes blamed on "bad paint." Subscription service found 62°F dew point at gun (needed ≤ -40°F). Added desiccant dryer + regulator-at-handle. Rejects fell from 18% to 2%. ROI: 7 months.

This echoes that body shop I mentioned earlier, where 100 PSI at tank became 28 PSI at trigger. Simple fixes: desiccant tower, fresh hose, regulator at handle. Orange peel became glass. Rejects dropped 90% in one week. Predictable maintenance costs aren't an expense; they're the difference between profit and panic.

Why Most Subscriptions Fail (And How to Avoid Them)

Not all programs deliver. Red flags:

- "One-size-fits-all" plans: Your 3HP pancake compressor needs different service than a 20HP rotary screw

- No dew point tracking: Humidity varies by season, static service intervals miss moisture spikes

- Tank-only focus: Ignoring pressure drop at tool means defects continue

Demand customization. If you're evaluating outcome-based contracts, see our compressor-as-a-service model analysis. A quality vendor will:

- Audit your actual tool demands (e.g., "You use DA sanders 2.3 hrs/day, here's the filter schedule")

- Provide monthly reports with pressure/dew point graphs

- Offer regulator-at-tool add-ons (non-negotiable for paint)

The Bottom Line: Stop Guessing, Start Measuring

Compressor subscriptions only deliver compressor subscription ROI when they're engineered for your air quality needs, not generic checklists. Insist on:

- Verified performance data at the tool, not just the tank

- Transparent failure metrics (e.g., "dew point stayed ≤ -40°F 98.7% of operating hours")

- Zero-defect commitments tied to service levels

I've helped shops turn compressor chaos into competitive advantage by treating air like a recipe: precise measurements, documented inputs, repeatable outputs. When clean, dry air flows at stable pressure from regulator to nozzle, you stop chasing defects. You create them.

Dry air, fewer defects. It's not a slogan, it's physics. Your subscription should guarantee it or refund you. Stop accepting "good enough" air. Your next flawless finish depends on it.

Ready to dissect your air system? Download my free Compressor Performance Scorecard, it quantifies pressure drop, moisture risk, and ROI potential for your exact setup. Includes spec sheets for regulator placement and filter staging. Get the Scorecard

Related Articles

Drone Manufacturing Compressors: Precision Air Quality Solutions

Reduce Compressor Cyber Insurance Premiums Through IIoT Security

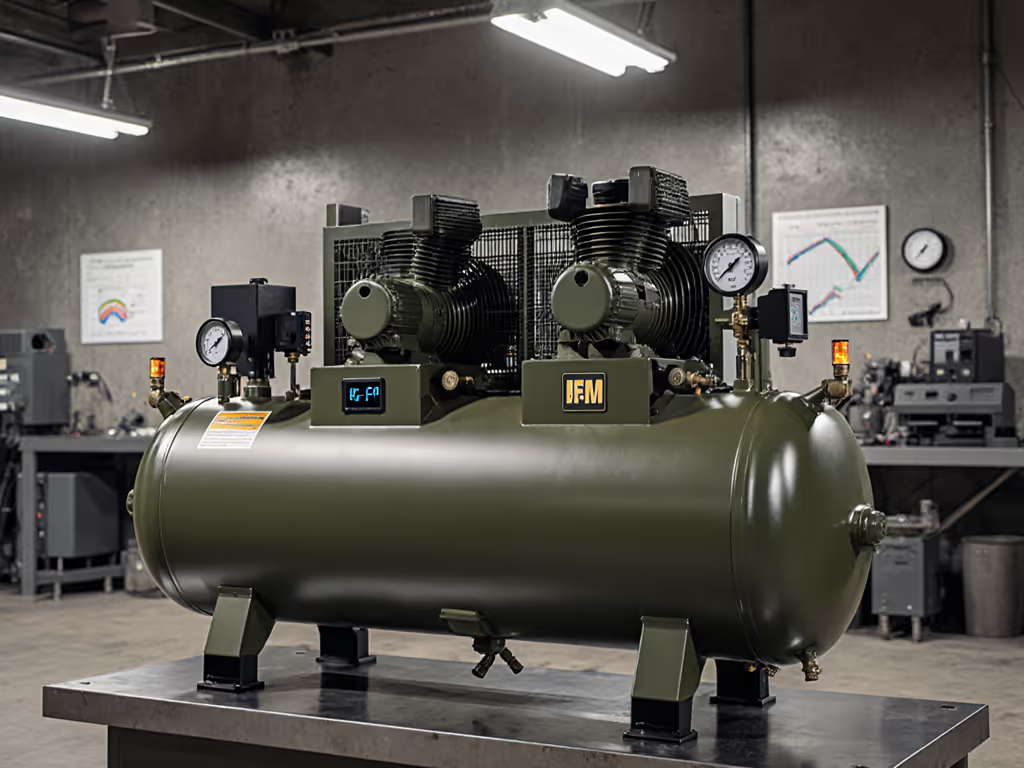

Military-Grade Air Compressors: Real CFM ROI Under MIL-STD