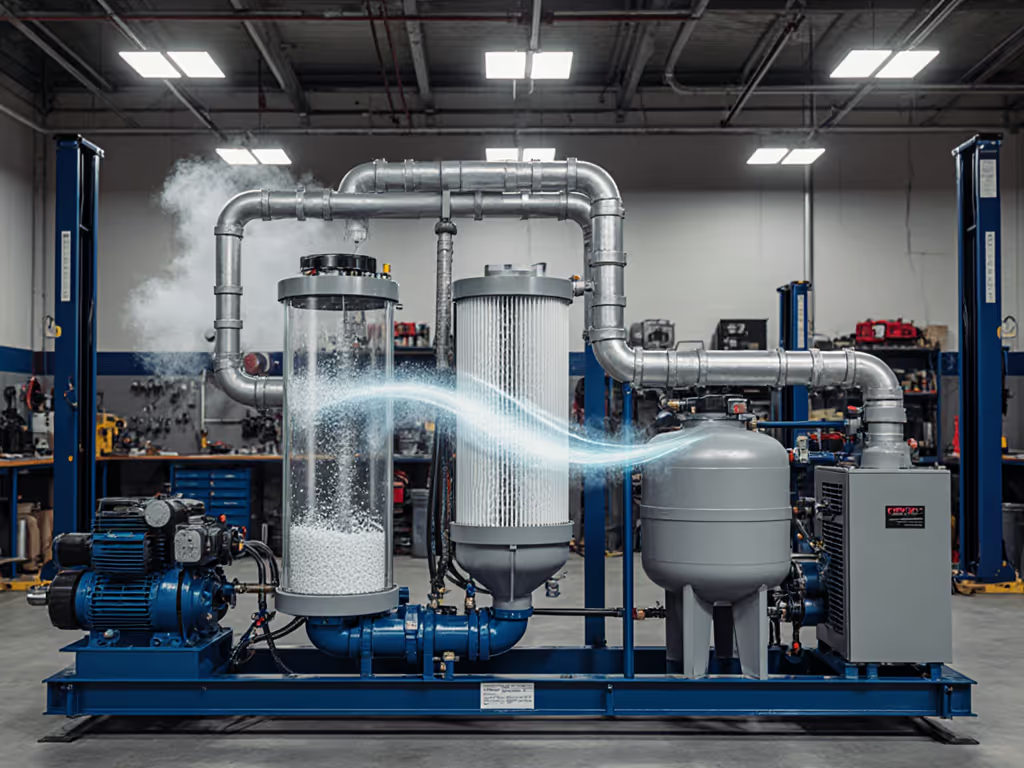

Multi-Stage Filtration: Stop Moisture & Particle Contamination

If your pneumatic tools stall mid-nail, your paint finish has fisheyes, or rust stains bloom inside your airline, your compressed air filtration system failed before you even turned on the compressor. The truth? Multi-stage air filtration isn't optional insurance. It is the backbone of uptime when moisture and particulates threaten your schedule. I've seen crews lose $500 in rework because a single $50 filter wasn't staged right for the task. Stop guessing. Start matching your air system to the job with field-proven staging steps.

Why Single-Stage Filters Sabotage Jobsite Reliability

Most contractors grab whatever coalescing filter fits their compressor outlet. Big mistake. Airborne contaminants hit your tools in waves:

- Stage 1: 5+ micron grit (sandblasting dust, sawdust)

- Stage 2: 0.5-5 micron oil aerosols (from piston compressors)

- Stage 3: Invisible water vapor (condensing at low temps or pressure drops)

A lone filter either clogs too fast (if sized for Stage 1) or lets fines through (if aimed at Stage 3). NASA's research proves this: particle removal efficiency plummets when one filter tries to handle all sizes. I once traced paint fisheyes on a $12K wrap job to a clogged coalescing stage that flooded the carbon filter downstream. If it trips a breaker at noon, it failed at dawn. You're not fixing filters, you are fixing poor staging.

Plan the power, then the air.

The Field Engineer's Air Purity Checklist

Before buying any filter, answer these:

-

What's your tool's maximum contaminant tolerance?

- Spray guns: ≤ 0.01 ppm oil, ≤ -40°F dew point

- Impact wrenches: ≤ 5 micron particles, ≤ 100 ppm oil

- Sandblasters: ≤ 40 micron grit (but zero moisture)

-

What's your compressor's output at working pressure?

- Example: A 5.5 HP twin-cylinder @ 90 PSI actually delivers 9 CFM, not the "16 CFM peak" on the box. Learn how to read specs correctly with our CFM vs PSI guide.

-

What's your ambient dew point?

- Humid Gulf Coast summer: 75°F dew point means 10x more condensate than Arizona winter

-

What's your duty cycle?

- 50% intermittent use (framing nailer) vs. 100% continuous (HVLP spray booth)

Step 1: Build Your Moisture Removal Cascade (It's Not Just About Dryers)

Forget desiccant dryers as your first line of defense. They are for final polishing, not bulk water removal. Here's how to cascade moisture control without bankrupting your power budget: Compare refrigerated, desiccant, and membrane options in our air dryer comparison to choose the right final stage.

Stage 1: Mechanical Separation (The $0 Fix)

- Install an aftercooler immediately post-compressor (within 3 ft of tank)

- Why it works: Cools 150°F+ air to 100°F, condensing 50% of vapor before it hits filters

- Field hack: Wrap copper lines in wet rags during summer, if water drips from the drain, it is working

Stage 2: Coalescing Filter Staging (Your Efficiency Lever)

| Filter Position | Micron Rating | Pressure Drop @ 20 CFM | Required For |

|---|---|---|---|

| Primary | 5 micron | 1.5 PSI | All oiled compressors |

| Secondary | 0.01 micron | 8 PSI | Painting, precision tools |

Critical rule: Never skip the 5-micron stage. Without it, the 0.01-micron filter floods in 10 minutes. I carry two 5-micron filters on my van rig (one for dusty sites, one clean backup). Rotate them weekly. For a full upkeep plan by compressor type, follow our maintenance schedule.

Stage 3: Final Vapor Control (Pick Your Poison)

- Refrigerated dryers: Best for <100 CFM jobs. Must pair with auto-drain, manual drains fail when crews "forget"

- Desiccant dryers: Only for -40°F dew points. Warning: Consumes 15-20% of your compressor's CFM for purge air

- Membrane dryers: Silent but tiny capacity. Ideal for 1/4" air lines on mobile rigs

Step 2: Match Particle Removal Stages to Your Tool's Weak Points

Don't filter to "HEPA": filter to tool failure thresholds. A framing nailer chokes on 40-micron grit. A die grinder seizes at 5 microns. If your application has defined purity classes, match your stages to ISO 8573 air quality standards. Here's how to stage:

The 3-Stage Particle Removal Protocol

-

Pre-Filter (50-75 micron):

- Must-have for: Roofing, demolition, outdoor sanding

- Sultan F1008 wall-mount filters trap swarf before it enters the main system

- Check monthly: If airflow drops 10%, replace (even if not "full")

-

Coalescing Core (0.01-0.3 micron):

- Critical for: All rotary screw compressors, piston compressors >5 HP

- Always install after moisture separation, water destroys filter media

- Field test: Hold white paper behind outlet. Any oil mist? Bypass is leaking.

-

Polishing Stage (0.01 micron + carbon):

- Non-negotiable for: Automotive paint, medical equipment

- AlphaPure's carbon stage removes VOCs that cause fisheyes

- Swap rule: Every 500 hours or when odor appears (not when "dirty")

The Smokemaster M67 industrial air filtration system skips stages 1 & 2 for light-duty tasks (e.g., buffing). But for heavy weld smoke? Its single-stage media overloads fast, proving why staging = longevity.

Step 3: Validate Your Power-to-Filtration Balance (Prevent Breaker Trips)

Here's where most mobile rigs die. Add filters, then add pressure drop, then the compressor works harder, then it trips GFCI. Your staging is useless if it outruns your power. Do this before mounting:

Power Validation Checklist

-

Calculate total amperage draw:

- Compressor LRA (Locked Rotor Amps) + filter pressure penalty

- Formula: Amps = (CFM x PSI) / (1714 x Efficiency) + 15%

- Example: 10 CFM @ 90 PSI = (10 x 90) / (1714 x 0.75) x 1.15 = 8.0 amps

-

Match wire gauge to distance:

Cord Length Max Amps Required Gauge 0-25 ft 15A 14 AWG 25-50 ft 15A 12 AWG 50+ ft 15A 10 AWG -

Generator test:

- Run compressor with filters at 75% load for 5 min

- Monitor voltage: If < 110V, undersized generator or cord

Real-world fix: On that concrete pour, we swapped 100 ft of 14 AWG for 50 ft of 10 AWG. Voltage drop vanished. No more GFCI trips at 9 AM.

Maintenance Schedules That Prevent Downtime (Not Just "Check Filters")

Stop reactive maintenance. Track these before failures:

| Component | Inspection Frequency | Critical Failure Sign | Field Fix |

|---|---|---|---|

| Coalescing filter | Every 100 hours | 15+ PSI drop | Replace media + check bypass |

| Auto-drain | Daily | Continuous dripping | Tap strainer; clean orifice |

| Desiccant beads | Weekly | Color change (blue to pink) | Rotate beds; replace if slow |

Spare parts non-negotiables for mobile rigs:

- 2x coalescing filter elements (5 and 0.01 micron)

- 1x drain valve rebuild kit

- 10 ft of 1/4" nylon airline + push-to-connect fittings

Final Verdict: Staging Saves Money Today

That crew using a single $80 filter lost $1,200 in paint redo. My staged system (pre-filter + coalescing + carbon) costs $220, but runs 18 months without downtime. Air purity optimization isn't about "perfect" air. It is about fit-for-task air that matches your tool's weaknesses, power constraints, and schedule. Test your current setup: If moisture appears during a 2-hour spray session, your cascade failed at Stage 1. If breakers trip, you ignored power validation.

Your Action Plan Before Monday

- Map your tool chain's contaminant limits (use the checklist on page 3)

- Install a pressure gauge between filter stages if drop >5 PSI, add a pre-filter

- Run a 10-minute voltage test on your longest cord

Plan the power, then the air. Your schedule depends on it.

Related Articles

Vertical Farming Compressors: Precision Humidity Control

Museum Preservation Compressors: Truth Beyond Specs

Quiet Film Set Compressors: Oil-Free Air Systems Compared