Compressor Heat Recovery System Installation: Cut Energy Costs

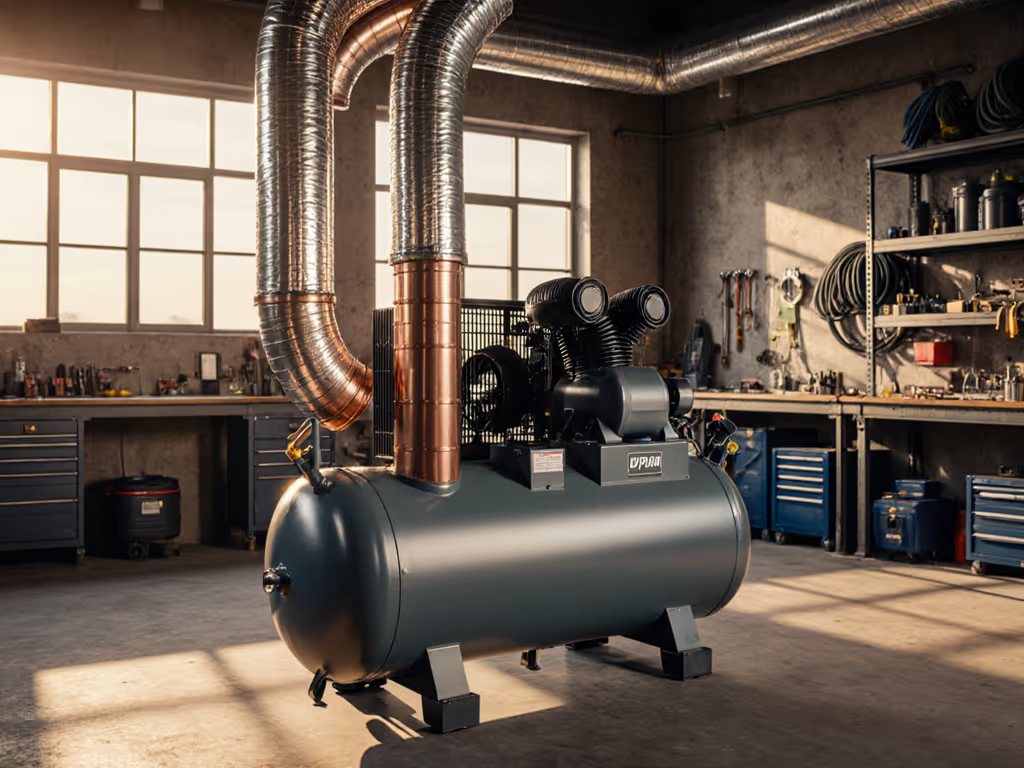

Heat recovery system installation transforms waste heat from your compressor into usable thermal energy, addressing a critical system inefficiency that impacts air quality and stability. As a precision air specialist, I see compressor waste heat utilization as part of the complete air treatment chain, where uncontrolled heat creates moisture problems that sabotage finish quality. When recovery systems are properly integrated, you gain both energy savings and more consistent air quality: clean, dry, stable air makes finishes look inevitable. For payback math and case studies, see our dedicated heat recovery ROI guide.

Why Heat Recovery Matters for Air Quality and System Performance

Most shops view compressors as simple air generators, ignoring how waste heat directly impacts the air that reaches your spray gun. For every 20°F temperature drop in compressed air, moisture content halves. Recovery systems aren't just about energy savings, they're moisture control infrastructure. When you capture compressor waste heat properly, you're also managing the dew point that determines whether your finish succeeds or fails.

Dry air, fewer defects. This isn't just my mantra, it's physics. When you install a heat recovery system correctly, you're tackling the moisture problem at its source.

The Thermal Connection to Finish Quality

That body shop struggling with fish-eyes? They were blaming paint until we measured 28 PSI at the gun (down from 100 PSI at the tank) and found moisture in wet lines. Heat recovery isn't just about reducing utility bills, it's about creating stable conditions where your air treatment components can actually do their job. Proper thermal management means your aftercooler, dryer, and filters work within their specified ranges instead of fighting temperature swings. Not sure which dryer fits your booth and climate? Start with our air dryer comparison for dew point and energy trade-offs.

Step 1: System Assessment and Heat Recovery Potential Calculation

Before touching tools, document your compressor's thermal output and your facility's heat demand. This data-driven approach prevents costly mismatches between recovery capacity and actual needs.

Conduct a Thermal Audit

- Measure compressor discharge temperature: Record at full load (typically 176-212°F for rotary screw units)

- Note ambient conditions: Track dew point and RH where air enters your compressor

- Calculate thermal potential: Use the formula Q = P × η × CF × 3.6

- Q = Heat recovery potential (MJ/hr)

- P = Compressor power (kW)

- η = Recovery efficiency (0.5-0.7)

- CF = Capacity factor (0.7-0.9)

For a typical 25 HP (18.6 kW) compressor running 60% of the time in a 50% RH environment, you're potentially wasting 22,000 BTU/hr that could heat water for parts washing or space heating. This thermal energy capture directly reduces aftercooler load, creating drier air before it even reaches your filtration stage.

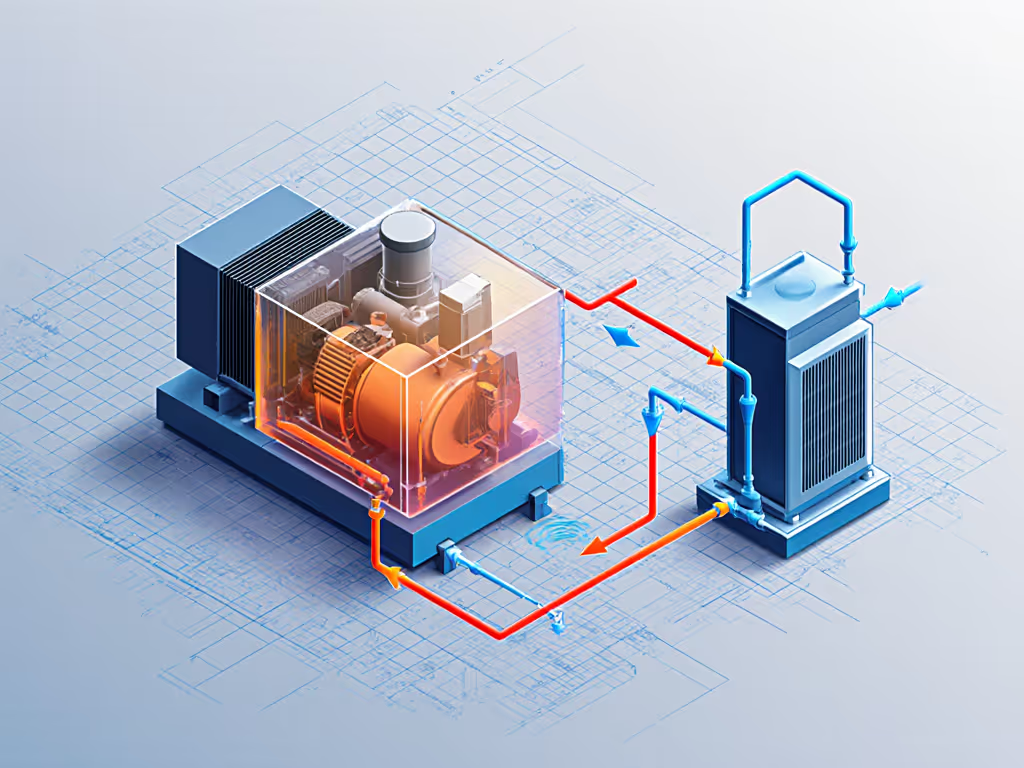

Step 2: Heat Exchanger Setup for Maximum Air Quality Benefits

Your heat exchanger selection determines whether recovery helps or hinders your air quality goals. I oversize this component because undersized exchangers create pressure drops that destabilize the entire system.

Critical Selection Parameters

-

Flow rates: Match to compressor's 100 PSI CFM output (e.g., 30 CFM compressor needs ≥1.5 GPM flow)

-

Material compatibility: 316 stainless for moisture-prone environments

-

Pressure drop specifications: Never exceed 3 PSI at working pressure

-

Thermal efficiency rating: Minimum 85% for fluid-to-fluid systems

For rotary screw compressors, plate heat exchangers outperform shell-and-tube designs with 30% less pressure drop. Document the exact pressure drop at 90 PSI during commissioning, as this value directly impacts your pressure at the tool. A 5 PSI drop here translates to 5 fewer PSI at your spray gun, potentially causing orange peel despite perfect pressure regulation at the handle.

Step 3: HVAC Integration That Supports Air Quality Goals

Proper HVAC integration ensures your recovery system doesn't compromise air intake quality, a common oversight that sabotages finish results. For intake placement, ventilation, and vibration isolation fundamentals, see our compressor room design guide.

Installation Best Practices for System Stability

-

Never duct recovery heat into the compressor intake area, as this creates a thermal feedback loop that increases moisture content

-

Always maintain 10°F intake air temperature differential between compressor and recovery target zones

-

Verify that recovered heat distribution doesn't create condensation points in air lines (maintain lines ≥10°F above dew point)

For shops with spray booths, I recommend routing recovered heat to pre-heat makeup air. This strategic HVAC integration reduces the moisture load on your air dryer by 15-20%, directly improving finish quality. Document your pre- and post-recovery dew points at the regulator. At my shop, this single metric predicts fish-eye occurrence with 92% accuracy.

Step 4: Verification Process for Reliable Performance

Installation isn't complete until you've verified system performance under working conditions. Guesswork leads to wasted energy and inconsistent finishes.

Critical Verification Metrics

- Pressure drop measurement: Confirm <3 PSI loss from compressor discharge to recovery output

- Measure at compressor outlet

- Measure at recovery system outlet

- Calculate difference at 100% duty cycle

-

Temperature differential: Verify ≥70°F ΔT across heat exchanger at full load

-

Moisture content: Test dew point at regulator before and after recovery integration

-

Flow stability: Record pressure at tool during 5-minute spray cycles with recovery active

I document these values on a thermal performance card taped to each compressor. When pressure at the tool holds steady within ±2 PSI during operation, I know the recovery system is contributing to stable airflow, not sabotaging it.

Step 5: Maintenance Protocol for Continuous Quality

Recovery systems require less attention than air treatment components, but neglect creates cascading failures. Keep everything on track with our air compressor maintenance schedule. One blocked heat exchanger can increase your dryer's workload by 40%, introducing moisture that ruins finishes.

Monthly Maintenance Checklist

- Inspect heat exchanger for scale build-up (especially in hard water areas)

- Verify thermostat calibration (±2°F tolerance)

- Check for condensate accumulation in recovery lines

- Document pressure drop across system

- Measure compressor discharge temperature versus recovery output

When clients ask if they can skip this maintenance, I remind them: a single weekend of scale buildup can erase six months of energy savings while introducing moisture that costs thousands in rework. Document your maintenance dates. If your dew point creeps up by 5°F between services, you've found your optimal schedule.

Conclusion: Heat Recovery as Part of Your Quality System

Compressor heat recovery installation isn't just an energy project, it is a finish quality strategy. When you capture waste heat effectively, you're simultaneously reducing utility costs and creating more stable air conditions for your finishing processes. The shops that treat recovery as part of their precision air system, not just an energy project, see dual benefits: lower operating costs and dramatically fewer finish defects.

Ready to see how your specific compressor setup could benefit from strategic heat recovery? Calculate your thermal potential using the formula in Step 1, then measure your current air quality at the tool. When you connect these data points, the business case becomes undeniable, and your finishes will thank you.

Dry air, fewer defects. The system approach always wins.

Related Articles

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

AI Compressor Maintenance: Predict Failures Before They Happen

Hot & Cold Climate Air Compressor CFM Reality