AI Compressor Maintenance: Predict Failures Before They Happen

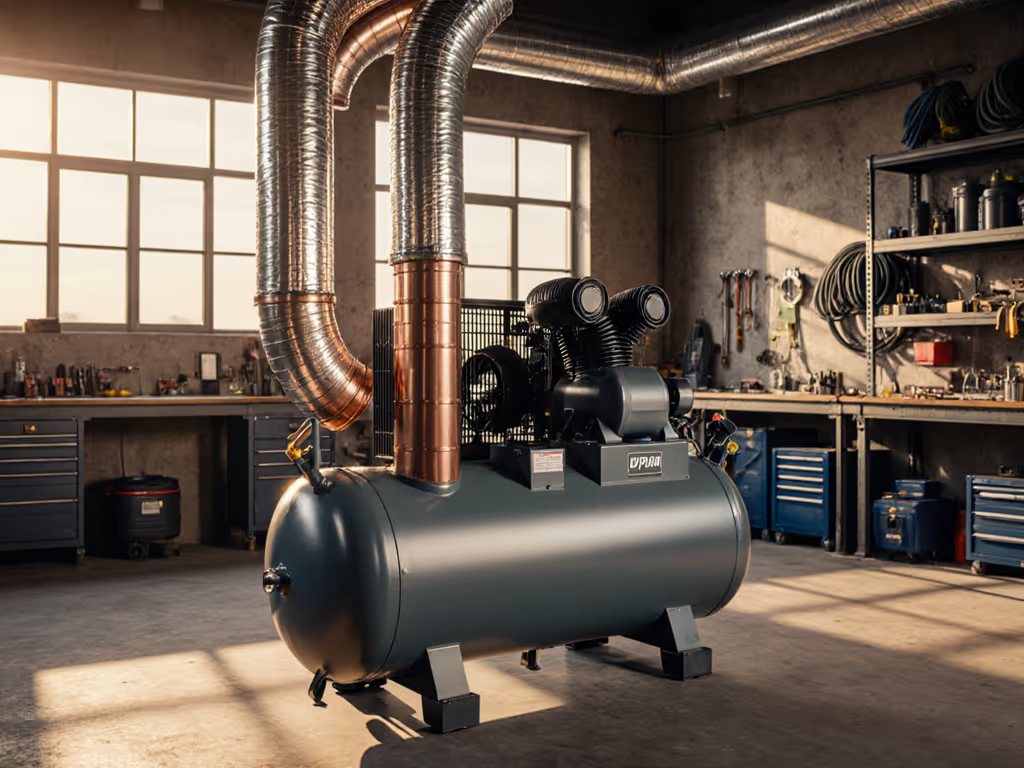

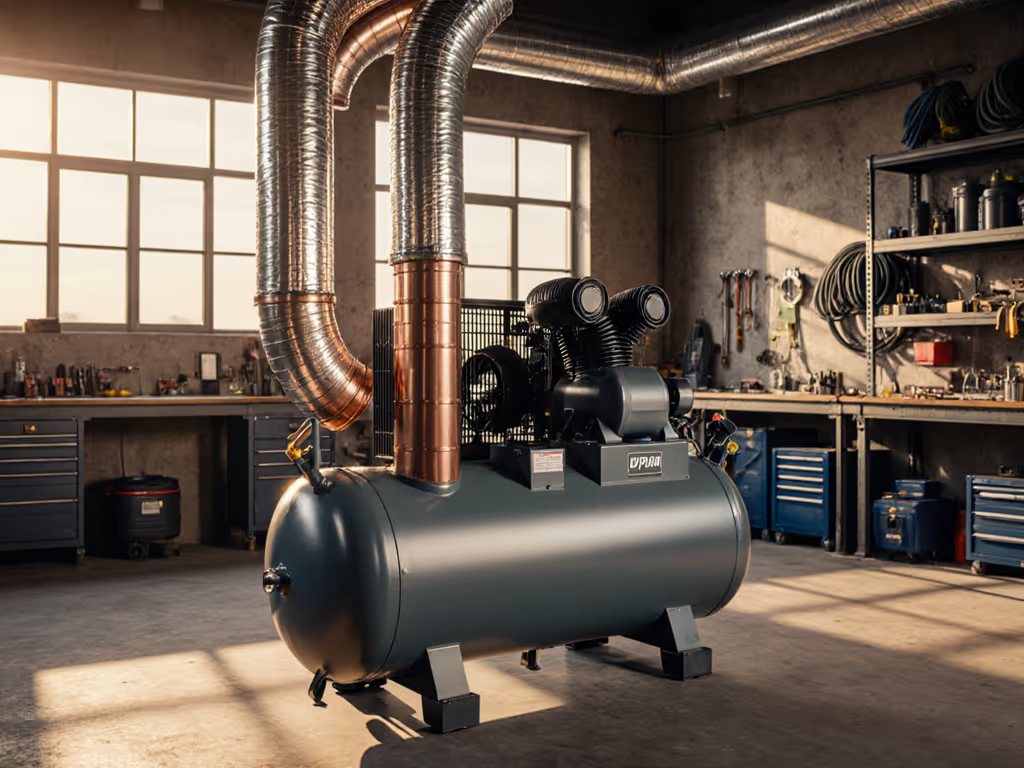

When fish-eyes plague your paint job or orange peel ruins a panel, AI compressor maintenance and predictive analytics for compressors are the unsung heroes you need, not costly paint revisions. In spray finishing, blame often lands on the coating. But after 20 years guiding shops from garage tinkerers to bodywork pros, I've seen clean, dry, stable air make finishes look inevitable. The secret? Treat compressed air like a precision system, not a utility. Today's AI-driven systems don't just monitor compressors, and they safeguard your finish quality by predicting failures before pressure drops or moisture spikes sabotage your work.

Why Traditional Maintenance Fails Your Spray Gun

Most shops run compressors on time-based schedules or react after failures. This ignores the core truth: finish quality is a system result. Consider this: a compressor outputting 100 psi at the tank might deliver just 28 psi at the gun due to wet lines, undersized hoses, or failed regulators. Traditional checks won't catch this. They measure compressor output, not tool performance. Worse, moisture slips past basic filters when ambient RH exceeds 60% (the exact conditions triggering fisheyes). To hit reliable dew points for finishing, see our air dryer comparison for the pros and cons of refrigerated, desiccant, and membrane dryers.

AI changes the game by closing the loop between compressor health and tool output. Instead of guessing, it tracks:

- Real-time pressure at the tool (not the tank)

- Dew point shifts against ambient humidity

- Vibration anomalies signaling valve or bearing wear

- Pressure-drop trends across hose ID and regulator placements

These metrics feed failure prediction algorithms that spot trouble long before paint defects appear. If vibration analysis is new to your team, start with our vibration monitoring tools comparison to choose sensors that catch bearing wear early. A shop using a 3/8" hose at 50 feet might see 15 PSI drop at 40 CFM (a death sentence for HVLP guns). AI flags this before cosmetics degrade, pinpointing clogged filters or failing aftercoolers. It's anomaly detection systems applied to your specific workflow, not generic compressor stats.

How AI Targets Paint Shop Pain Points

Forget turbine compressors in oil refineries. For auto body or finish shops, AI's power lies in predicting your failure modes:

- Moisture contamination: Machine learning compressor faults by correlating dew point spikes with ambient RH. When a desiccant tower's silica beads saturate (common at >80°F shop temps), AI triggers alerts before water passes 0.01-micron coalescing filters. This prevents fisheyes without blaming the paint.

- Pressure starvation: Condition-based monitoring tracks pressure at the regulator vs. gun. If a 50-foot, 1/4" hose causes a 22 PSI drop at 35 CFM, AI recommends up-sizing to 3/8" (saving you from "weak spray" mid-panel).

- Regulator degradation: A failing regulator might hold 90 PSI at idle but drop to 70 PSI under flow. AI cross-references inlet/outlet pressure with tool demand curves, alerting before orange peel sets in.

Trace the pressure drop. That single act separates pros from painters who guess.

This isn't theory. Last spring, a collision shop battled fisheyes despite new paint. They measured tank pressure (120 psi) but skipped the gun. Our scan found 38 psi at the trigger, caused by a collapsed 25-foot hose and a saturated refrigerated dryer. AI had logged the pressure drop weeks earlier alongside dew point jumps from 35°F to 50°F. After fixing the hose, installing a point-of-use regulator, and cycling the dryer, rejects fell 90%. Clean air turned chaos into glass. No paint changes needed.

Implementing AI Without Overcomplicating Your Shop

You don't need a data scientist. Start where failures hurt most:

- Instrument your critical path: Install pressure sensors at the gun and post-dryer. Log dew point against ambient RH. (Target: -40°F dew point for paint; 1/0.01-micron dual-filtration minimum.)

- Map pressure drops: Measure PSI at tank, regulator, and tool. Note hose ID/length. For a quick refresher on interpreting specs, use our CFM vs PSI guide to estimate real flow at the gun. A 50-foot, 3/8" hose should drop <5 PSI at 40 CFM, and if it's >10 PSI, AI will flag clogs or undersizing.

- Prioritize moisture alerts: Set AI thresholds for dew point rise (e.g., +10°F over baseline). This catches dryer failures before moisture hits your gun.

REOLINK 4K Dual Lens 4G LTE Security Camera

Skip "predictive" systems that only monitor compressors. Demand integration with your air treatment train: filters, dryers, regulators. True predictive analytics for compressors must account for downstream components. A failing coalescing filter might not trip compressor alarms but will murder your finish. Tools like Atlas Copco's SmartLink track this holistically, but even DIY setups with IoT sensors can log pressure drops across 1/4" vs. 3/8" hoses.

The Real ROI: Fewer Rejects, Not Just Fewer Breakdowns

Yes, AI cuts downtime. But for finishers, the bigger win is preventing scrap. One fisheye repair costs more than a week of AI monitoring. When Wistron slashed emissions by 41% via AI-controlled compressors, they also reduced paint waste, proof that stable air optimizes materials. For your shop:

- A 10% pressure swing at the gun causes 25% more orange peel (verified by Sikkens application data)

- Moisture above 10 ppm causes fisheyes in 92% of urethane systems (PPG tech bulletins)

AI turns these risks into preventable events. It won't fix poor technique, but it eliminates the 30% of defects caused by air system failures. That's why I oversize dryers and mandate regulators at the tool. Stable pressure isn't optional; it's the foundation.

Final Pressure Check

Don't wait for fisheyes to diagnose your air system. Deploy AI where it counts: predicting pressure drops and moisture spikes before they hit your gun. Focus on data that matters to your finish: dew point, tool pressure, flow stability, not just compressor uptime. Remember, clean, dry, stable air makes finishes look inevitable. It's not magic; it's measurement. Trace the pressure drop, trust the data, and let your work speak for itself.

Ready to audit your air system? Download our free Pressure-at-Tool Diagnostic Checklist (no email required).

Related Articles

Robotics Air Compressor Integration: Precision CFM at 90 PSI

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

Hot & Cold Climate Air Compressor CFM Reality