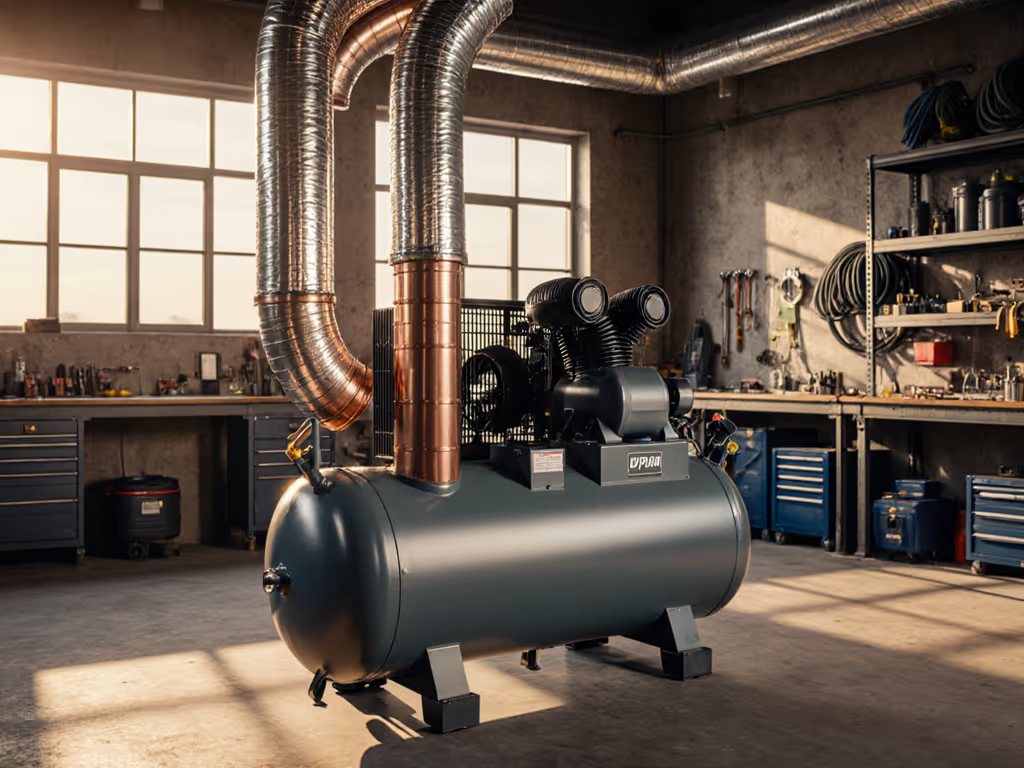

Installation, Maintenance, Troubleshooting & Service

Practical guidance for setting up compressors, keeping them running, fixing common issues, and finding qualified service providers.

Explore Other Topics

Compressor Basics & Sizing

Foundational knowledge to understand compressors and choose the right capacity, including how they work, key specs, and sizing methods.

Safety, Efficiency & Accessories

Safety and compliance essentials, energy-efficiency best practices, and accessories/air treatment components that improve system performance.

Home & DIY Buying Guides

Buyer advice and product picks tailored to homeowners and light-duty, indoor or residential use.

Professional & Industrial Comparisons

Technology and use-case comparisons for commercial and industrial buyers, including brand reliability and application-specific recommendations.