Your Solar Air Compressor ROI: No Marketing Fluff

Let's cut through the greenwashing noise: renewable energy compressor ROI isn't about slapping solar panels on your existing compressor and calling it sustainable. And solar-powered air compressor systems aren't just "free energy" solutions peddled by salespeople with glossy brochures. Real ROI comes from precise load matching, duty cycle economics, and total system costs (not peak horsepower claims or inflated CFM ratings). I've watched too many shops install underperforming systems that looked great on paper but bled money in the first 18 months. Pay once for uptime, not forever for waste and noise.

The Hidden Cost of Compressed Air

Your Compressor is Probably Your Most Expensive Tool

Think about it: your $600 pancake compressor might cost $0.03 per minute to run, but during peak summer months when you're running HVAC testing equipment alongside paint sprayers? That number jumps to $0.08, without you realizing it. Most shops measure compressor costs only at startup, not under sustained load. This is where the disconnect happens between "stated" and "actual" costs.

I recently audited a mobile detailing van that switched to a solar-assisted system. The owner thought he was saving money with a "high-efficiency" 5HP reciprocating compressor. Reality check:

- Startup amperage: 42A (tripping his 50A inverter)

- Running amperage at 90 PSI: 28A

- Actual duty cycle required: 68% (vs. rated 50%)

- Daily runtime: 5.5 hours

- Grid electricity cost: $0.18/kWh

Annual cost calculation:

(28A x 120V x 5.5h x 250 days) / 1000 = 4,620 kWh

4,620 kWh x $0.18 = $831.60/year

But here's what he didn't account for: compressor inefficiency at partial load. That unit was cycling every 90 seconds because it couldn't sustain pressure during dual-tool operation. Each startup surge added 15% more energy consumption. The true cost? $1,075/year... and he was still dealing with inconsistent pressure when using dual orbital buffers.

The Solar Trap: Common Missteps

Solar integrations often fail because shops apply residential solar logic to industrial loads. Here's what goes wrong:

- Mismatched capacity: Panel arrays sized for "average daily use" but failing during high-demand periods

- Inverter limitations: 120V/15A circuits overloaded by compressor startup surges

- Battery mismanagement: Lead-acid banks stressed by frequent deep discharges

- Poor load profiling: No duty cycle logging before system design

One roofing contractor I consulted installed 3 kW of solar thinking it would power his 5HP compressor. He neglected to measure:

- Inrush current: 65A (peaking at 7.8 kW)

- Working pressure: 110 PSI (requiring 12% more energy than 90 PSI)

- Leak rate: 8.7 CFM (22% of total capacity)

The result? His solar system powered lights and tools, but defaulted to grid power during compressor operation. The "off-grid" claim was pure fiction.

Pay once for uptime, not forever for waste and noise.

Calculating True Solar Air Compressor ROI (No Fluff)

Step 1: Map Your Actual Load Profile

Forget nameplate ratings. Grab a clamp meter and log:

- Peak amperage at startup (critical for inverter sizing)

- Running amperage at working pressure (e.g., 90 PSI vs 120 PSI)

- Duty cycle during typical operations (use a timer for 3-5 workdays)

- Leak-down rate (shut off system, measure pressure drop per minute)

Here's a real-world example from a cabinet shop (similar to my cautionary tale):

| Metric | Measured Value |

|---|---|

| Startup Amps | 58A |

| Running Amps @ 90 PSI | 41A |

| Required Duty Cycle | 57% |

| Total Leak Rate | 14.2 CFM |

| Daily Runtime | 6.2 hours |

Their mistake? They bought a used rotary screw compressor advertised as "energy efficient," but didn't verify these numbers. The electric bill told the truth: $1,850 more annually than their previous (smaller) system. Why? The oversized unit cycled constantly at partial load, a death sentence for efficiency.

Step 2: Calculate Current Grid Costs

Normalize your usage to working pressure. Most compressors draw 3-5% more power per 10 PSI above 90 PSI. For accurate comparisons:

Adjusted kWh = (Measured kWh) x (Working PSI / 90)

Example calculation:

- Compressor running at 110 PSI

- Measured consumption: 1.2 kWh/hour

- Working pressure adjustment: 110/90 = 1.22

- True consumption: 1.2 kWh x 1.22 = 1.46 kWh/hour

Now calculate annual cost:

1.46 kWh/hour x 6.2 hours/day x 250 days = 2,263 kWh

2,263 kWh x $0.16/kWh = $362.08/year

But wait... we haven't accounted for leaks. That 14.2 CFM leak rate? At $0.16/kWh, it costs $479.20/year to pressurize air that never does useful work.

Step 3: Model Solar Integration Economics

Critical Questions You Must Answer

- What's your actual compressor load profile? (Not "average"... hourly breakdown)

- When does your highest demand occur? (Does it align with solar production?)

- What's your grid electricity rate structure? (Time-of-use charges? Demand fees?)

The Real ROI Formula

Annual Savings = (Grid Cost - Solar Cost) - Maintenance Differential

Simple Payback = (Net System Cost) / Annual Savings

True ROI = [(Lifetime Savings - Net Cost) / Net Cost] x 100%

Let's run the numbers for a correctly sized system:

- Net solar system cost: $12,500 (after ITC)

- Current grid cost: $841.28/year (operation + leaks)

- Projected solar cost: $187.50/year (battery replacement + minimal grid top-up)

- Annual savings: $653.78

- Simple payback: 19.1 months

But here's what 90% of analyses miss: duty cycle matching. If your compressor runs only during daylight hours (when solar production peaks), your effective battery bank can be 40% smaller. That's $2,100 saved upfront.

Step 4: Factor in Sustainability Incentives (The Real Ones)

Don't fall for "green compressor incentives" hype. Focus on what actually impacts your bottom line:

- Federal Investment Tax Credit (ITC): 30% of system cost (2025 rate)

- Modified Accelerated Cost-Recovery System (MACRS): 84% first-year depreciation

- State-specific programs: Like California's SGIP for battery storage

My cabinet shop example qualified for:

- $3,750 ITC (30% of $12,500)

- $10,500 MACRS deduction

- $1,200 state rebate

Total effective cost: $12,500 - $3,750 - $1,200 = $7,550

Suddenly that 19.1-month payback drops to 11.6 months. That's why TCO beats MSRP every time.

Making It Work: Practical Implementation

System Design Rules That Actually Matter

- Size for peak demand, not average: Your compressor must handle the highest simultaneous tool usage

- Match solar production to compressor schedule: If you spray paint at 10 AM, design for that load

- Include leak remediation in budget: Fixing leaks costs 1/10th of adding generation capacity

- Prioritize inverter compatibility: Must handle 3x running amps for 5 seconds

I helped a paint booth operator implement this exact approach. Before:

- 7.5HP compressor cycling every 75 seconds

- $1,920/year in electricity

- Persistent fisheyes from moisture issues

After solar integration:

- 5HP two-stage compressor with variable speed drive

- 4 kW solar array + 10 kWh LFP battery

- Leak rate reduced to 2.1 CFM

- Total cost: $14,200 (after incentives)

- Annual savings: $1,685

- Payback: 10.2 months

TCO beats MSRP because we modeled the actual load profile instead of falling for "peak HP" marketing.

Maintenance Realities (No Sugarcoating)

Solar compressors aren't "maintenance free." Here's what you'll actually spend:

| Component | Interval | Cost |

|---|---|---|

| Air filters | Quarterly | $28 |

| Oil (if applicable) | Annually | $65 |

| Battery replacement | Every 7 years | $2,200 |

| Inverter capacitor check | Bi-annually | $120 |

Contrast this with a grid-only system:

| Component | Interval | Cost |

|---|---|---|

| Higher electricity costs | Monthly | +$1,200/year |

| More frequent pump rebuilds | Every 3 years | +$850 |

| Noise mitigation costs | Ongoing | $300/year |

The solar system's slightly higher maintenance is offset by dramatically lower operating costs, and fewer component failures due to stable power delivery.

Final Verdict: When Solar Compressors Actually Make Sense

After reviewing dozens of installations, I've found solar-powered air compressors deliver compelling renewable energy compressor ROI only when these conditions are met:

✅ Your compressor runs >4 hours/day during daylight hours

✅ Electricity costs exceed $0.15/kWh

✅ You've addressed all major air leaks first

✅ Your shop has unobstructed roof space or ground area

✅ You can claim tax incentives (ITC + MACRS)

The break-even point isn't theoretical, it's in the spreadsheet. A sustainable compressor investment requires hard data, not sustainability claims. I've seen too many shops "save" $2,000 upfront on a compressor only to pay $300 more monthly in electricity and downtime. That's not savings, it's financing your own inefficiency.

Go measure your actual amperage. Log your duty cycle. Calculate your true CFM needs at working pressure. If you need help interpreting specs, use our CFM vs PSI guide to translate ratings into real tool requirements. Then... and only then... can you model a solar integration that delivers real utility savings calculation results. The cheapest system is the one that meets spec for years with minimal waste.

TCO beats MSRP. Always.

Related Articles

Drone Manufacturing Compressors: Precision Air Quality Solutions

Reduce Compressor Cyber Insurance Premiums Through IIoT Security

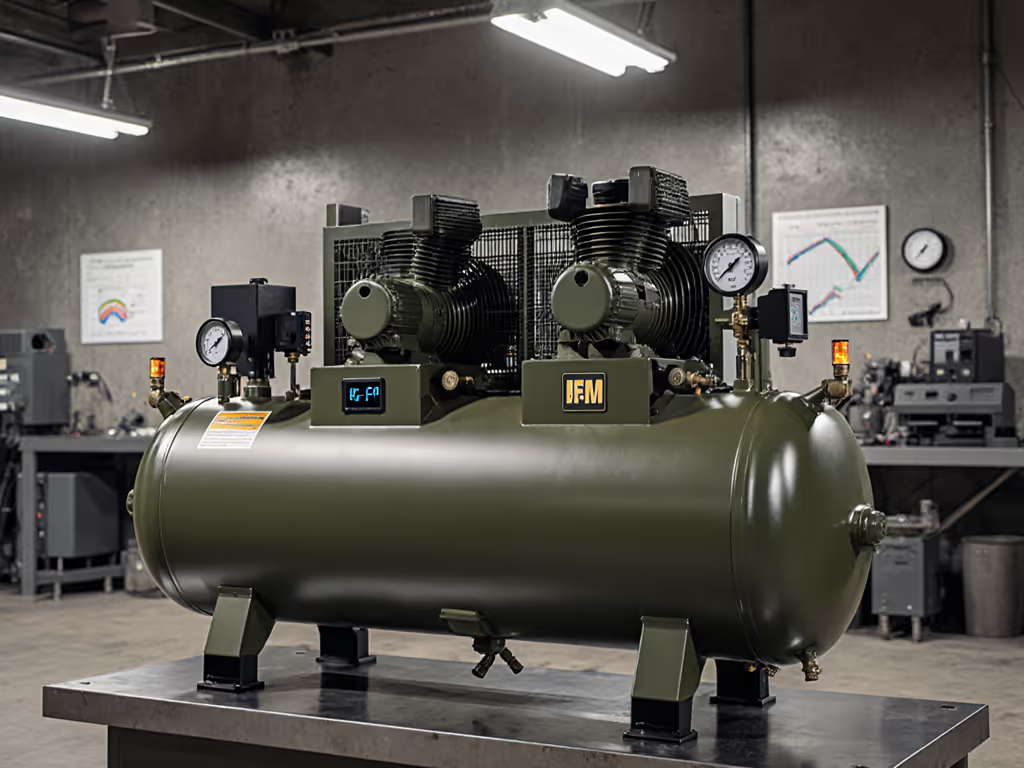

Military-Grade Air Compressors: Real CFM ROI Under MIL-STD