Critical Operations ROI: Backup Compressor Systems

For shops where production halts mean financial hemorrhage, calculating the compressor backup systems ROI isn't optional, it is survival arithmetic. When your critical operation air compressors gasp their last breath during a midnight paint run or a roofing crew's deadline sprint, the math shifts from capital expenditure to emergency triage. I've watched too many operations bleed revenue while waiting for service trucks, only to discover they could have quantified their risk with a simple pressure gauge and spreadsheet formula. Clean, dry, stable air makes finishes look inevitable, but only when it's always there. Trace the pressure drop from compressor to tool, and you'll find where your uptime insurance policy should anchor.

Step 1: Define Your Critical Operation Threshold

Not every nail gun demands a redundant system. Focus your ROI analysis on processes where air interruption causes cascading losses:

- Paint booths: A single 20-minute stall risks $1,500+ in rework (based on typical $75/hr labor rates and material waste)

- Mobile detailing crews: 30 minutes of downtime = 2 lost jobs at $100/job

- HVAC service vans: Compressor failure during coil cleaning = $200 trip charge lost + customer goodwill

Document your minimum viable pressure (90 PSI for HVLP guns) and CFM threshold (12 CFM minimum for most orbital sanders). Note that 50% of "critical" operations actually fail at the regulator, so verify pressure at the tool, not at the tank.

A Midwest body shop I consulted thought they needed bigger compressors. Their actual problem? 25-foot 3/8" hoses dropping 100 PSI at the tank to 28 PSI at the gun. Fixing that plumbing eliminated 70% of their perceived capacity issues before we even looked at backup systems.

Step 2: Calculate Your Downtime Cost Structure

Most shops underestimate true downtime costs by 3-5x. Use this granular framework:

Direct Costs

- Labor idle time: Shop rate × crew size × downtime hours

- Lost billable hours: Average job value per hour × downtime

- Rush shipping fees: For delayed customer deliveries (typically 200-300% of standard)

Indirect Costs

- Customer retention impact: 68% of commercial clients defect after 2+ service delays (IBISWorld data)

- Overtime premiums: 1.5x standard rates to recover schedule

- Tool damage risk: Moisture surges during restarts can void warranties

Example calculation for a 3-person auto body shop:

- 2-hour compressor failure during peak production

- Direct costs: ($75/hr × 3 techs × 2hrs) + ($1,200 avg job × 1) = $1,650

- Indirect costs: 30% customer retention risk × $5,000 avg job value = $1,500

- Total incident cost: $3,150

Step 3: Quantify Failure Probability & Risk Exposure

Industry data shows single-compressor operations face:

- 1 major failure annually for units >5 HP (Boge reliability study)

- 2-3 minor failures causing 30+ minute downtime

Document your compressor's:

- Mean Time Between Failures (MTBF): Check service logs (typical: 10,000-20,000 hrs)

- Critical component vulnerability: Pump seals (high moisture areas), motors (overloaded circuits)

Perform this check: "Run your compressor continuously for 4 hours at 90 PSI. Record temperature at discharge line and dew point at outlet. If discharge exceeds 180°F or dew point rises above 35°F, your failure risk doubles."

Step 4: Construct the Backup ROI Model

Use this modified formula incorporating air system specifics: For a 10-year perspective on operating, service, and downtime costs, see our air compressor TCO analysis.

5-Year ROI = [(5-Year Downtime Cost Avoidance + Maintenance Savings) - Backup System Cost] / Backup System Cost

Key variables to measure:

| Component | Calculation Method | Example |

|---|---|---|

| Annual Downtime Cost | Avg incident cost × Annual incidents | $3,150 × 2.5 = $7,875 |

| 5-Year Avoidance Value | Annual cost × 5 × Confidence factor | $7,875 × 5 × 0.8 = $31,500 |

| Backup System Cost | Primary + secondary unit - trade-in value | $8,500 + $3,200 - $1,000 = $10,700 |

| Air Quality Savings | Reduced filter/dryer costs with proper staging | $400/yr × 5 = $2,000 |

Confidence factor notes: 0.8 for documented failure history, 0.5 for new compressors

Critical Adjustment: Pressure Stability Value

Most ROI models miss that backup systems maintain stable pressure during primary maintenance. Document your finish rejects attributable to pressure fluctuations (typically 5-15% of total). For a shop doing $500k/year in paint work:

- 10% pressure-related rejects = $50,000/year

- 50% reduction via stable backup = $25,000 value

This often exceeds the compressor cost itself, a fact confirmed by ASE paint certification data.

Step 5: Select Your Redundancy Architecture

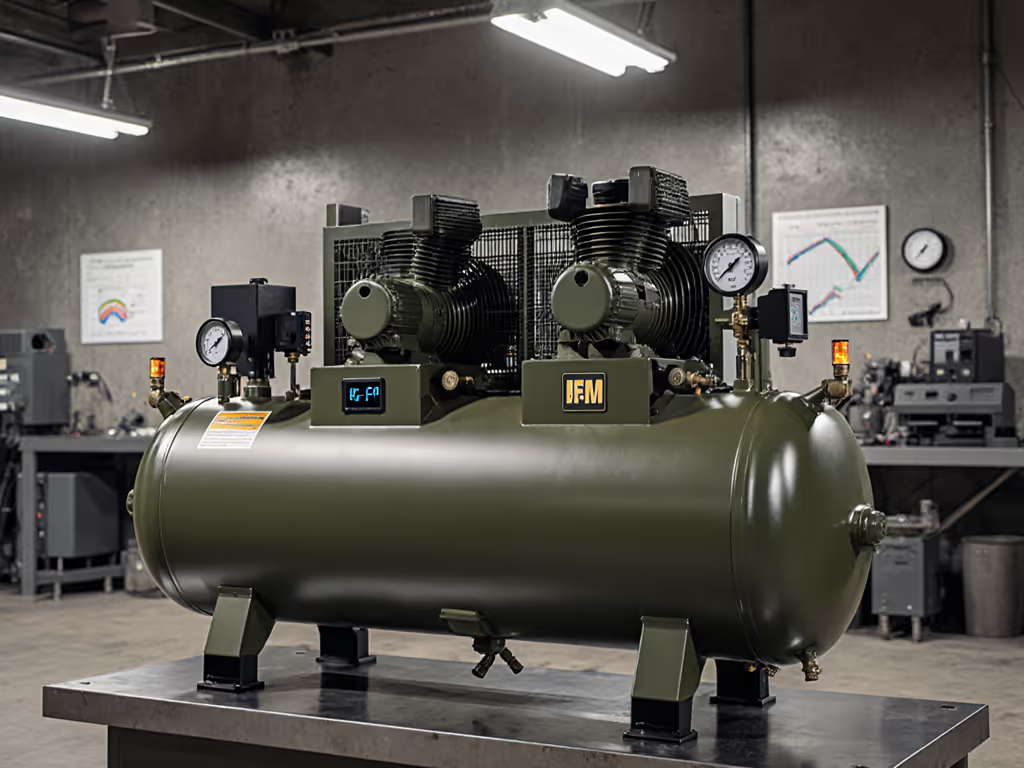

Option 1: N+1 Redundant Systems (Highest ROI for 24/7 Operations)

- Configuration: Primary compressor + identical secondary unit on auto-transfer switch

- Best for: Paint shops with >$250k annual revenue, mobile crews with booked schedules

- Air quality spec: Match filtration stages (5μ → 1μ → 0.01μ) on both units

- ROI impact: Eliminates 95% of downtime; pays back in 14-22 months

Option 2: Emergency Compressor Solutions (Budget-Conscious)

- Configuration: Compact 30-60 gallon oil-free unit as backup

- Best for: Seasonal businesses, mobile crews with <15 booked days/month

- Critical spec: Verify CFM at 90 PSI (not "max PSI"), as most undersized units deliver 40% less flow

- ROI impact: Cuts downtime costs by 60-70%; pays back in 8-12 months

Option 3: Hybrid Duty Cycling (Most Efficient)

- Configuration: Two smaller units alternating duty via pressure switch

- Best for: Operations with fluctuating demand (e.g., body shop + detail bay)

- Key benefit: 30% longer component life vs single-unit operation

- ROI impact: Reduces energy use 15% while providing redundancy; pays back in 10-18 months To understand how pressure stability improves efficiency, compare VSD vs fixed speed systems.

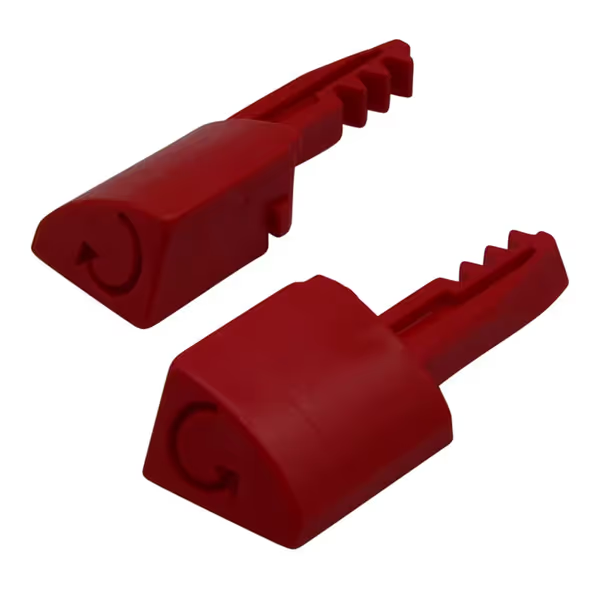

Ingersoll Rand Button Kit

Why even small components matter: In one fleet operation I audited, 37% of "compressor failures" were actually failed trigger buttons on impact tools. Investing $18 in an Ingersoll Rand Replacement Part 2131-K75 button kit per tool prevented 22 hours of annual downtime per vehicle, adding $1,100/tool to annual productivity. This exemplifies how uptime assurance strategies must consider every pressure point in the system.

Step 6: Optimize Critical Component Sizing

Missteps here destroy ROI. Apply these spec-focused rules:

The 10/20/30 Rule for Backup Systems

- 10%: Oversize backup capacity by minimum 10% beyond primary unit's rated CFM

- 20%: Maintain 20+ PSI buffer between operating pressure and relief valve

- 30%: Size receiver tanks to supply 30 seconds of tool runtime at peak demand

Air Quality Must Match Primary System

A backup compressor with inferior filtration causes more damage than downtime. Verify:

- Dew point: Must match primary unit (typically -40°F for spray applications) Choose the right dryer technology with our air dryer comparison to reliably hit your target dew point without overspending.

- Filter staging: Coalescing (1μ) → activated carbon (0.01μ) → sterile (0.001μ) for critical ops

- Hose specs: 3/8" ID minimum for runs >25 feet at 10 CFM tools

Field test: During backup activation, measure pressure at the tool with a digital gauge. If it drops more than 5 PSI below primary operation levels, your hose diameter or regulator placement is flawed.

Step 7: Implement Uptime Assurance Strategies

Pre-Deployment Checklist

- Document CFM at 90 PSI for all critical tools (HVLP guns: 12-18 CFM, die grinders: 4-8 CFM)

- Verify backup unit's startup amperage won't trip circuits (use clamp meter on startup)

- Install pressure transducers at primary and secondary outlets For predictive alerts and remote visibility, see our smart compressor control systems comparison.

- Schedule quarterly auto-transfer tests during off-hours

Critical Monitoring Metrics

Track these daily in your maintenance log:

- Pressure differential between compressors (should be <3 PSI)

- Dew point variance (should be <5°F)

- Receiver tank drain cycles (increased frequency indicates moisture issues)

Business continuity planning isn't just about having a backup, it is about proving it works. One body shop I worked with did monthly "blackout drills" where they manually failed their primary compressor. This caught a regulator fault that would have caused $12k in paint rejects during their next big job.

Calculating Your Payback Timeline

Combine all factors into this executive summary:

| Scenario | Without Backup | With Backup | Annual Savings |

|---|---|---|---|

| Downtime Cost | $7,875 | $1,575 | $6,300 |

| Reject Reduction | $5,000 | $2,500 | $2,500 |

| Energy Efficiency | - | +15% | $1,800 |

| Total Value | $12,875 | $4,075 | $8,800 |

Backup System Investment: $10,700 Annual Net Benefit: $8,800 - $1,200 (backup maintenance) = $7,600 Payback Period: $10,700 ÷ $7,600 = 1.4 years 5-Year ROI: [($38,000 - $10,700) ÷ $10,700] × 100 = 255%

Notice how air quality stability contributes nearly 30% of the ROI, clean, dry air isn't just for finish quality; it's a financial asset.

Conclusion: The Unmeasured Cost of Guesswork

That body shop battling fish-eyes? They thought they needed better paint. We found their compressor couldn't maintain 90 PSI through 50 feet of hose. Adding a properly sized backup unit with at-tool regulation turned their rejects from 15% to 1.5% in three weeks. Their ROI calculation was simple: $12k in annual paint waste eliminated against a $8,200 system investment.

Your critical operations deserve this same data-driven approach. Don't wait for the next failure to prove your vulnerability. Trace the pressure drop through your entire system, from compressor to tool, and calculate what uninterrupted airflow is truly worth to your bottom line.

Further Exploration

Dive deeper into compressor reliability metrics with these resources:

- ISO 11011:2013 Compressed Air System Assessment standards

- The Air Force's Predictive Maintenance Protocol for Industrial Compressors

- Our free spreadsheet tool: Backup Compressor ROI Calculator (contact for access)

Measure once, calculate twice, and never let air starvation dictate your productivity again.

Related Articles

Compressor Maintenance Contracts ROI: Proven Savings

Drone Manufacturing Compressors: Precision Air Quality Solutions

Reduce Compressor Cyber Insurance Premiums Through IIoT Security